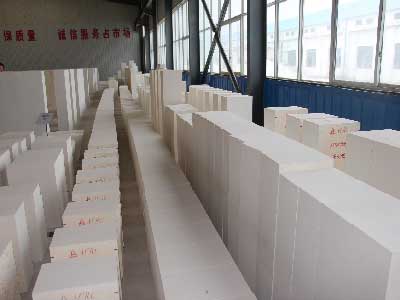

Refractory materials refer to inorganic non-metallic materials of which the refractoriness is more than 1500 ℃. Different refractory materials have different properties, which affect the application of the refractory materials. And the properties of the refractories can be reflected in the thermal performance, physical properties, chemical characteristics, mechanical properties, and high temperature characteristics. In addition, costs of the initial installation labor, maintenance, repair, and replacement are factors that must be considered.

Refractory applications can be reflected in the thermal equipment of the metallurgy industry, power industry, construction materials, chemical industry, glass industry, nonferrous industry, cement industry, ceramic industry, and petrochemical industry. And according to the characteristics of refractories, there are different applications of refractories. When choosing a kind of refractory brick, no matter the refractory brick suppliers or the users take different reasons about the productions into consideration, such as the parts of the application, characteristics of the bricks, manufacturing as well as operation conditions, and the refractory bricks price. Because all of the reasons play important roles in the thermal equipment, such as extending service life, improving the working efficiency, saving energy and reducing cost.

Refractory materials are basic materials in the development of iron and steel industry, nonferrous industry, building materials industry, petrochemical industry, and electric power industry, etc. Different refractories are chosen in different industries according to the features of themselves.

In terms of the iron and steel industry, refractory materials can be used in the following parts: the coke oven, blast furnace, hot blast furnace, ladle, metal mixer, heating furnace, torpedo pot, converter, electric furnace, secondary refining furnace, open hearth furnace, and arc furnace, etc.

To the nonferrous metal industry, refractory materials are widely used in the nonferrous metal smelting furnace, electrolytic furnace, electric melting furnace, and reverberatory furnace, etc.

As for the building materials industry, refractory materials can be used in the cement kiln, glass kiln, and ceramic kiln, etc.

And to the power industry, refractory materials are used in the boiler, and circulating fluidized bed, etc.

With development of the industries, industrial refractory is playing an increasing important role in different fields. It means that the manufacturers and the users must choose the materials correctly, to improve production efficiency, save energy, and reduce cost.