Corundum brick is also known as alumina refractory products. It is featured with high temperature resistance, high refractoriness under load, wear and corrosion resistance, and high mechanical strength, etc. corundum bricks can be used in the blast furnace, hot blast stove, tunnel kiln, and glass kiln, etc.

Corundum Refractory Bricks Specification

| Brands

Items |

High Purity Corundum Brick | High Purity Corundum Brick | Sinter Corundum Brick |

| AI2O3 % ≥ | 99 | 95 | 90 |

| SiO2 % ≤ | 0.2 | 3.5 | 8 |

| Fe2O3 % ≤ | 0.2 | 0.2 | 0.2 |

| Bulk Density g/cm3 ≥ | 3.2 | 3.15 | 3 |

| Apparent Porosity % ≤ | 19 | 18 | 18 |

| Cold crushing strength Mpa ≥ | 100 | 100 | 100 |

| Refractoriness Under Load(0.2mpa 0.6%)≥ | 1700 | 1700 | 1700 |

Corundum Bricks Classifications

Corundum brick is refractory material of which the main crystal phase is the corundum.

According to the manufacturing process, it can be divided into fused corundum brick, fused rebounded corundum brick, and sintered corundum brick. Fused corundum brick is made of industrial alumina and quartz powder, which is processed in the arc furnace by melting, and then through casting, annealing and the final mechanical process, being produced into the required shape and size. Fused rebounded corundum brick is made from the crushed fused corundum pellet and powder, together with small amount of clay and binder, after fully mixed and then be molded by brick molding machine, and the adobe drying temperature is about 1700 ~ 1800 ℃.

Based on the mineral, there are zirconia corundum bricks, corundum mullite bricks, etc.

Based on manufacturing process

- Fused corundum brick

- Fused rebounded corundum brick

- Sintered corundum brick

Based on minerals

- Zirconia corundum bricks

- Corundum mullite bricks,etc.

Corundum Bricks Composition and Properties

Corundum brick refers to refractory brick that contains AL2O3 more than 90%, so it is also called the alumina product. The main materials of the corundum brick are brown corundum, white corundum, high alumina corundum, zirconia corundum, monocrystalline fused alumina, and microcrystalline fused alumina.

It belongs to neutral refractory with good chemical stability, which is resistant to erosion of the acid and alkali slag and solvent, as well as the other chemicals.

Corundum brick has series of excellent performance, such as low thermal conductivity, high mechanical strength, high hardness and good electrical insulation performance. In addition, it is excellent in abrasion resistance, oxidation resistance, and corrosion resistance. It has good cold compressive strength, about 340 MPa, and high refractoriness under load, which is about 1700℃.

AL2O3: More than 90%

Properties

- Low thermal conductivity

- High mechanical strength

- High hardness, high RUL

- Excellent in abrasion resistance, and oxidation resistance.

Corundum Refractory Bricks Applications

Corundum brick can be used in the following parts:

- Bosh of the blast furnace

- Hot blast stove, tunnel kiln

- High-temperature carbonization furnace

- Hearth of the heating furnace

- Glass melting furnace

- Secondary refining furnace

- Petrochemical industrial furnace

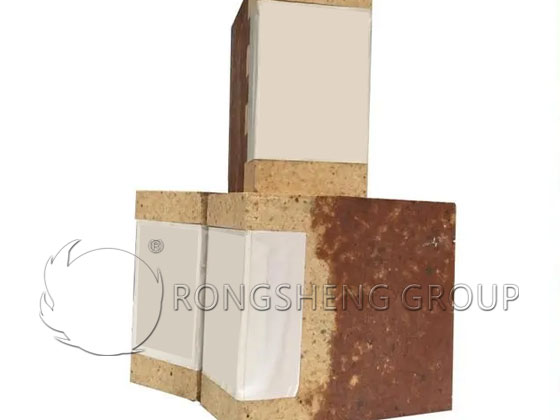

Corundum Refractory Bricks Supplier

Zhengzhou Rongsheng Kiln Refractory Co. Ltd, is a professional corundum bricks supplier. It is established in the early 90s of twenty century, located in the foot of Mount Song, a place of Xinmi city, which is in the middle of Zhengshao Expressway. The abundant high quality materials and convenient transportation, neighboring the Longhai and Jingguang railway lines, provide favorable conditions for the production of the refractory materials. After 20 years of hardworking and development, it has become a comprehensive enterprise producing refractory materials in metallurgy, building materials, electric power and chemical industry, etc.

There are about 1262 employees, including senior technical personnel 65, high-tech workers 80 and complete physical and chemical testing equipment and advanced detection methods. The credit rating is AAA grade, and the economic indicators and the enterprise technical force, namely the scale keep the leading position in the domestic industry.

Its major business are shaped heat bricks, unshaped refractory materials, refractory balls, and insulation materials.

Unshaped Refractory Products

- Refractory castable

- High alumina cement

- Refractory mortar

- Acid refractory castable

- Various monolithic refractories

- Calcined bauxite aggregate, etc.

Shaped Refractory Products

- Alumina products

- Silicon refractory products

- Fireclay refractory products

- Magnesia refractory products

- Mullite bricks

- Carbon refractory bircks, etc.

Refractory Ceramic Fibers

- Refractory ceramic fiber blanket

- Refractory board

- Refractory fiber rope, etc.

Advantages of RS

- RS is experienced in the international trade for about 20 years’ of hard working;

- RS is boast of the natural resources, advanced equipment and the professional team;

- RS runs strictly according to the standard of ISO;

- RS sales its products abroad by convenient transportation, neighboring the Transportation hub;

- RS provides all-around services to the customers efficiently and timely;

- RS has always been adhering to the business purpose of honesty, respectful, innovation, and dedication.

It provides superior corundum bricks, professional information and all-around services winning good reputation at home and abroad. Rongsheng has established cooperative relations with countries from southeast Asia and other countries and regions.

By scientific management, sound customer information management system and abundant products, Rongsheng provides satisfactory, timely, and efficient service about the corundum bricks to the consumers.

We are looking forward to establishing cooperation with you!