Mullite brick is a high alumina refractory with mullite as main crystalline phase. Generally, the alumina content is between 65% and 75%. In addition to mullite, the lower alumina also contains a small amount of glass phase and calcite. The higher alumina content also contains a small amount of corundum. Mullite refractory bricks high fire resistance, up to 1790℃ above. The initial temperature of load softening is 1600 ~ 1700℃. Normal temperature compressive strength 70 ~ 260MPa. Good thermal shock resistance.

This series of refractory bricks are mainly used in the top of hot blast furnace, blast furnace body and bottom, glass melting furnace regenerator, ceramic sintering furnace, dead corner lining of petroleum cracking system, etc. Mullite is a mineral formed by aluminosilicates at high temperatures. When aluminosilicates are artificially heated, mullite is formed. Natural mullite crystals are elongated needles and radiating clusters. Since there is very little natural mullite, it is usually synthesized by sintering or capacitance processes. Mullite ore is used to produce high temperature refractory materials.

Since mullite is the main crystalline phase of mullite refractory bricks, the properties of products are mainly determined by mullite. Mullite is the only stable compound in the Al2O3-SiO2 system under atmospheric pressure and oxidizing atmosphere. Mullite brick has a high fire resistance, up to 1790℃ above. The initial temperature of load softening is 1600 ~ 1700℃. Normal temperature compressive strength 70 ~ 260MPa. Good thermal shock resistance.

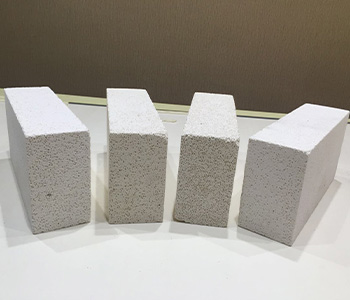

The mullite refractory bricks produced by our factory is made of natural high-quality bauxite, which is homogenized at various levels and washed into brick bricks on a brick press. After drying, the brick is sintered at a high temperature above 1750℃ in tunnel kiln. After cooling, the products need to be checked and selected block by block, which has the characteristics of large volume density, stable quality, good thermal shock stability, small creep value at high temperature and good resistance to chemical corrosion. After testing and using, the product has reached all kinds of technical indexes of similar products. It is the first choice of novel refractory in the refractory industry and the ideal raw material for the production of all kinds of shaped and unshaped refractory, advanced sanitary ware body, precision casting model and other refractory products.

The high temperature mullite thermal insulation brick produced by mullite has the characteristics of high temperature resistance, high strength, low thermal conductivity, remarkable energy saving effect, etc. It is suitable for lining of petroleum crack furnace, metallurgical hot air furnace, ceramic roller kiln, tunnel kiln, electric porcelain drawer kiln, glass crucible kiln and various electric furnaces, and can contact flame directly. We are a high quality refractory brick manufacturer, strict control of product quality, welcome to consult and purchase.