In the world of high-temperature applications, the selection of the right refractory material can make a significant difference in the performance and efficiency of the equipment. Graphite refractory bricks and fire clay bricks are two of the most commonly used materials in this space, but which one is the better option? In this essay, we’ll explore the key differences between these two types of bricks and analyze their advantages and disadvantages to help you make an informed decision.

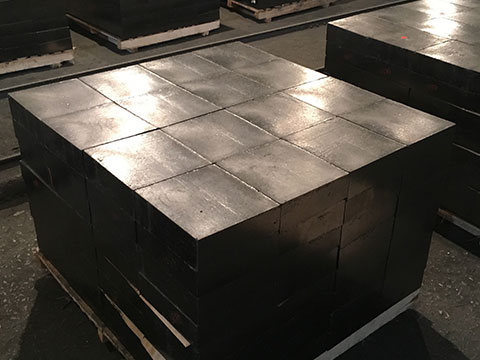

Graphite Refractory Bricks

Graphite refractory bricks are made of high-purity graphite and have excellent thermal conductivity and heat resistance. They are capable of withstanding temperatures up to 3000°C and are ideal for use in applications such as glass manufacturing, steelmaking, and petrochemical refining. Graphite refractory bricks are also known for their excellent resistance to chemical corrosion, making them an ideal choice for environments where the material will be exposed to harsh chemicals and acids.

Fire Clay Bricks

On the other hand, fire clay bricks are made of clay and other natural materials and are more commonly used in low-temperature applications. They are capable of withstanding temperatures up to 1300°C and are ideal for use in fireplaces, ovens, and other similar applications. Fire clay bricks are also relatively inexpensive and widely available, making them a popular choice for many applications.

When it comes to selecting the right material for your application, several factors come into play. The first and most important consideration is the temperature range of your application. If you’re working with temperatures above 1300°C, then graphite refractory bricks are the better choice due to their superior heat resistance.

Another critical factor to consider is the environment in which the bricks will be used. If your application involves exposure to harsh chemicals or acids, then graphite refractory bricks are a better option due to their excellent resistance to chemical corrosion. Fire clay bricks, on the other hand, are more susceptible to chemical damage and may not be suitable for use in such environments.

Cost is also a factor to consider when choosing between these two types of bricks. While graphite refractory bricks are more expensive than fire clay bricks, they offer superior performance and durability in high-temperature applications. Therefore, if your application involves high-temperature environments, investing in graphite refractory bricks may be a wise decision.

In conclusion, choosing the right refractory material for your application is critical to ensure optimal performance and efficiency. While fire clay bricks are suitable for low-temperature applications and are relatively inexpensive, graphite refractory bricks offer superior heat resistance and chemical corrosion resistance, making them the better choice for high-temperature applications. However, the cost factor should also be taken into account when making a decision. Ultimately, it’s up to you to weigh the pros and cons of each option and choose the one that best meets your needs.

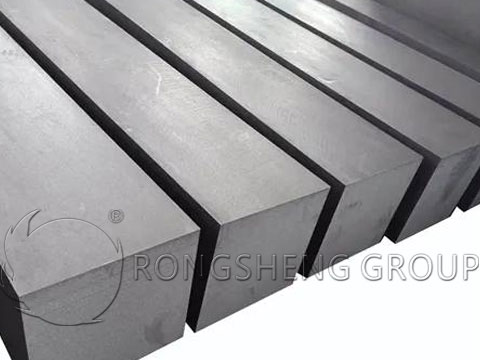

Where to Buy Graphite Blocks

Graphite blocks are widely used in various industrial applications, such as in the manufacturing of steel, glass, and electronic products. The high thermal conductivity and low thermal expansion properties of graphite make it an ideal material for high-temperature applications. However, finding a reliable source for high-quality graphite blocks can be a challenge. In this essay, we will discuss where to buy graphite blocks and what factors to consider when selecting a supplier.

One of the most common places to buy graphite blocks is through online marketplaces such as Alibaba, Amazon, or eBay. These platforms offer a wide range of options, from different sizes to various grades of graphite, and allow you to compare prices and suppliers easily. However, buying from an online marketplace comes with certain risks, including the lack of control over the quality of the products and the reliability of the suppliers.

Another option for purchasing graphite blocks is through specialized graphite manufacturers and suppliers. Rongsheng Refractory Bricks Manufacturer is one of the reliable manufacturers of refractory bricks, with both production and sales. We provide our customers with high-quality graphite blocks at the most competitive prices, and also customer services. These companies have a deeper understanding of the material and its applications and can provide technical expertise to help you select the right grade and size of graphite block for your needs. They can also offer customization options, such as shaping, machining, or coating, to ensure the product meets your specific requirements.

When selecting a supplier for graphite blocks, there are several factors to consider to ensure the quality and reliability of the product. Firstly, consider the supplier’s experience and reputation in the industry. Look for suppliers with a long history of producing high-quality graphite products and positive customer reviews.

Secondly, consider the supplier’s production capacity and lead times. You want to ensure that the supplier can meet your demands, whether it’s for a single block or a large quantity, and that they can deliver the products within the timeframe you require.

Thirdly, consider the supplier’s quality control procedures. Look for suppliers who have strict quality control standards in place to ensure that their products meet or exceed industry standards. This includes testing the products for impurities, density, and strength to ensure their suitability for high-temperature applications.

In conclusion, finding a reliable source for high-quality graphite blocks is critical to ensure optimal performance and efficiency in your industrial applications. Online marketplaces offer a wide range of options, but they come with certain risks. Specialized graphite manufacturers and suppliers provide technical expertise and customization options, but it’s important to consider their experience, production capacity, lead times, and quality control procedures. By weighing these factors carefully, you can select a supplier that meets your needs and provides you with the high-quality graphite blocks you require.