The manufacturing and production of Alumina Bubble Bricks not only solved the problem of high thermal conductivity but also addressed the issues of operating temperature and compressive strength in lightweight insulation materials. The application of alumina hollow sphere refractory materials in high-temperature kiln equipment has been well-proven in high-temperature energy-saving downdraft kilns, shuttle kilns, molybdenum wire furnaces, tungsten rod furnaces, induction furnaces, nitriding furnaces, and other similar equipment.

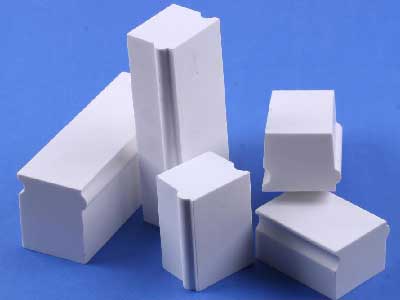

Alumina Bubble Bricks

Alumina Bubble Bricks are excellent thermal insulation materials, with a thermal conductivity far lower than ordinary corundum bricks.

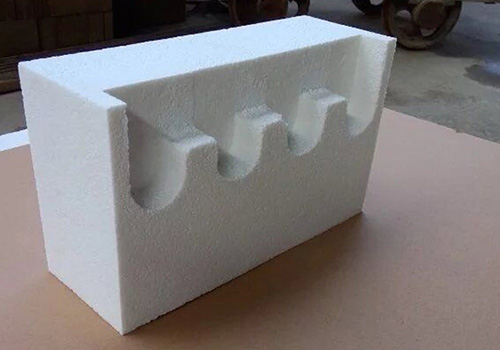

Simultaneously, Alumina Bubble Bricks possess excellent high-temperature resistance and flexural and compressive strength, belonging to the category of lightweight corundum insulating bricks. The sintering temperature is approximately 1730-1750 degrees Celsius; the bulk density is around 1.2-1.6, significantly lighter than the bulk density of corundum-mullite bricks, which easily reach around 3.0. It has been calculated that one cubic meter of alumina hollow sphere bricks used for kiln construction is 1.5 tons lighter than corundum bricks; the flexural strength is approximately 5 MPa. Due to their lightweight, thermal insulation, energy-saving properties, and good strength, they are widely used in the working linings of high-temperature kilns and in the treatment of flues used for heat exchange in high-temperature kilns.

Rongsheng Alumina Bubble Bricks are primarily made from high-quality alumina hollow spheres. They are produced using organic binders and various additives, and after molding and drying, are sintered at a temperature of 1730-1750°C.

Advantages: At the same density, Rongsheng Alumina Bubble Bricks have lower thermal conductivity and more locked, stagnant air pockets within their internal structure, resulting in better energy efficiency. This is mainly attributed to our professional raw material formulation, batching, and molding process.

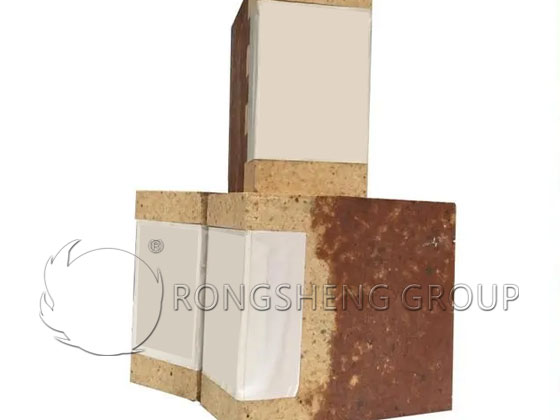

Are Alumina Bubble Bricks the same as high-alumina bricks?

No, they are not the same product.

High-Alumina Bricks

High-alumina bricks are aluminosilicate refractory materials with an aluminum oxide (Al2O3) content higher than 48%. Refractory bricks with an alumina content greater than 90% are called corundum bricks. High-alumina bricks are generally classified into three grades based on their Al2O3 content: Grade I – Al2O3 content > 75%; Grade II – Al2O3 content 60–75%; Grade III – Al2O3 content 48–60%.

Alumina Bubble Bricks

Alumina Bubble Bricks are made primarily from alumina hollow spheres and alumina powder, combined with other binders, and fired at 1750 degrees Celsius. They have an Al2O3 content higher than 90% and are a type of ultra-high temperature energy-saving insulation material.

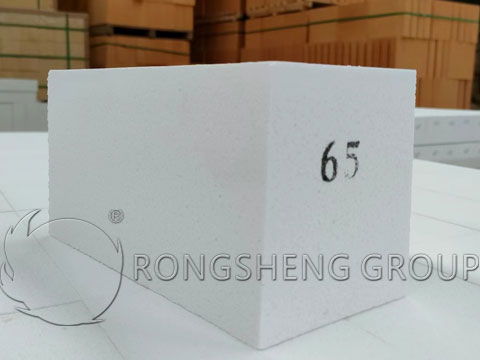

Ultralight Alumina Bubble Bricks

With the widespread application of lithium-ion battery cathode materials, lithium-ion battery cathode material manufacturers are facing increasing pressure to conserve energy and reduce emissions. Traditional alumina hollow sphere bricks used in cathode material kilns have a bulk density of at least 1.5, resulting in high thermal conductivity and less than ideal insulation performance. Furthermore, they are difficult to cut and process during construction, leading to high energy consumption and production costs. Lithium-ion battery cathode material kiln manufacturers urgently need lightweight Alumina Bubble Bricks that offer better energy efficiency and insulation while reducing production costs.

Rongsheng Refractory Factory’s ultralight Alumina Bubble Bricks possess excellent high-temperature resistance and thermal insulation properties, and can be directly used in the working layer of lithium-ion battery kilns. They significantly reduce furnace weight, modify the structure, save materials, conserve energy, and reduce costs.

Advantages of Ultra-Lightweight Alumina Bubble Bricks:

- Lower bulk density: Approximately 0.8 g/cm³, compared to at least 1.5 g/cm³ for traditional 99% alumina hollow sphere bricks. This significantly reduces furnace weight, saving materials, energy, and costs.

- Better thermal shock resistance compared to traditional 1.5 g/cm³ 99% Alumina Bubble Bricks.

- Extremely low thermal conductivity: Only 30% of traditional products. The thermal conductivity of a traditional 1.5 g/cm³ 99% Alumina Bubble Brick at 400℃ is 0.78. Lower thermal conductivity results in better insulation, with this brick offering three times the insulation performance of traditional bricks. The same furnace layer thickness allows for lower cold surface temperatures and greater energy savings. Alternatively, the insulation layer can be made thinner.

- Superior on-site cutting and processing performance. It can be cut and processed as easily as mullite lightweight bricks, depending on the actual on-site conditions. Traditional alumina hollow sphere products have poor processing performance and are difficult to cut and install on-site.

Compared to traditional Alumina Bubble Bricks, Rongsheng Refractory Factory’s ultra-lightweight Alumina Bubble Bricks, with their superior energy-saving and insulation properties and unique product advantages, can significantly reduce production costs for lithium-ion battery cathode material manufacturers and cathode material kiln manufacturers. They are undoubtedly the best choice for refractory and insulation applications in lithium-ion battery cathode material kilns.

If you also need lighter and more energy-efficient insulation furnace lining materials, please contact Rongsheng Refractory Factory for free solutions, samples, and quotations.