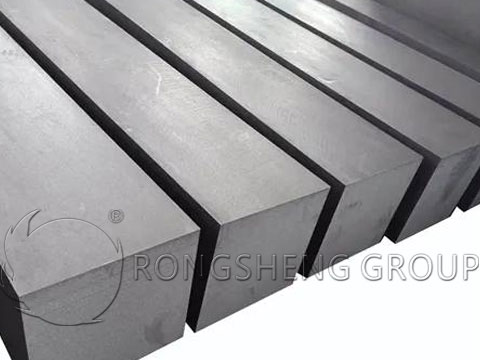

Low carbon magnesia carbon brick generally refers to a type of low-carbon composite material composed of magnesia and graphite as the main raw materials, adding a certain amount of metal additives, and combining with organic binders.

The Origin of Low Carbon Magnesia Carbon Brick

With the progress of smelting technology and new requirements for refractory materials, the following problems have been found in the long-term application of traditional magnesia carbon bricks.

- ①The high thermal conductivity increases heat loss and increases the tapping temperature. The resulting increase in energy consumption also increases a series of problems such as the erosion of refractory materials.

- ②As the lining material of special refining furnaces, such as smelting high-quality clean steel and ultra-low carbon steel in the VOD refining ladle, it will cause carbon increase problems.

- ③ Consume a lot of precious graphite resources.

In view of the above situation, in recent years, the development of low carbon magnesia carbon bricks with low carbon content and excellent performance for refined ladle has attracted the attention of domestic and foreign industries.

Application of Low Carbon Magnesia Carbon Brick

In recent years, with Japan as a representative, low carbon magnesia carbon brick using nanotechnology has developed significantly. The low-carbon magnesia-carbon bricks used can be roughly divided into two categories.

① Under the conditions of use, low-carbon magnesia-carbon bricks combined with nano-carbon fibers are formed in situ. The wc =1% in this kind of brick, the service life on the VOD ladle is twice that of the traditional magnesia chrome brick.

②Nano-structured matrix low carbon magnesia carbon brick, in the brick wc=3%~5%. In Japan, this kind of brick has been widely used in RH refining furnace as a substitute for magnesia chrome brick. Its service life is significantly better than traditional magnesia chrome bricks.

In recent years, the development and application of domestic low carbon magnesia carbon bricks have also made great progress. By using nano-scale clay brick carbon sources and high-efficiency antioxidants, low-carbon magnesia-carbon bricks with wc=4% to 6% have been successfully applied to the slag line and clad wall of 120 t VOD refining ladle. The smelting steel grades are 304, 304L, 316, 409, 409 L, 410, and other stainless steel grades, and the maximum smelting temperature is 1750℃. The service life of the developed low carbon magnesia carbon bricks is equivalent to that of imported magnesia-calcium bricks.

Features of Non-carbon Ladle Built with Low Carbon Magnesia Carbon Bricks

Spinel and corundum are used as the matrix of refractory bricks for the body and bottom of the non-carbon ladle, and low-carbon magnesia-carbon bricks are used for the slag line of the ladle. Spinel and corundum have high high-temperature strength, good thermal shock resistance, stable structure, and can effectively resist molten steel agitation and erosion. In terms of ingredients, add a certain amount of FMgO and FAl2O3. During high-temperature use, the in-situ spinel is generated, and its volume expands slightly. Densification of the prefabricated bricks can be used to prevent the penetration of FeO and CaO in the slag to the greatest extent, and achieve better corrosion resistance and permeability resistance.

Low-carbon magnesia-carbon bricks are used in the ladle slag line. Compared with traditional MgO-C bricks, low carbon MgO-C bricks have lower carbon content. When the aggregate is tightly packed, the mutual contact rate is relatively high; when used at high temperatures, its elastic modulus will increase significantly. Low-carbon MgO-C bricks use this feature to improve carbon dispersion, so as to make up for the shortcomings of insufficient carbon content, to resist slag penetration and structural spalling.

Performance comparison between low carbon magnesia carbon brick and magnesia-rich dolomite unburned brick

Low carbon magnesia carbon bricks use high-purity fused magnesia and composite carbon as the main raw materials. The matrix is made by adding composite antioxidants and reinforcing agents, using phenolic resin as the binding agent, and after high-pressure molding and baking treatment at 200°C.

Magnesium-rich dolomite unfired bricks use high-purity fused magnesia and rotary kiln calcined dolomite as the main raw materials. The matrix is made by adding composite antioxidants and reinforcing agents, using modified liquid asphalt as the binder, and then being subjected to baking treatment at 250°C after high-pressure molding.

There are experiments to test the slag resistance of two kinds of bricks through the static crucible method. The test condition is 1650℃ for 3h. The steel slag used in the test is a VOD steel slag of a special steel grade. Its chemical composition (w) is: CaO: 63.34%, SiO2: 2.94%, Al2O3: 19.82%, MgO: 6.69%, MnO: 0.17%. The cross-sectional photos of the two bricks after the slag resistance test are shown in Figure 2. The measured erosion widths of low-carbon magnesia-carbon bricks and magnesia-rich dolomite unburned bricks are 1.10 and 1.05mm, respectively, indicating that the slag erosion resistance of the two bricks is basically equivalent. Observing the residues in the two crucibles from Figure 2, it is found that the amount of residues in the low-carbon magnesia-carbon bricks is more than that in the magnesia-rich dolomite unburned bricks. It is inferred from this that the low-carbon magnesia-carbon brick can meet the requirements of the smelting process.

Rongsheng Refractory Brick Manufacturer

Rongsheng, as experienced refractory material production and sales manufacturer, always starts from the customer’s point of view and provides customers with high-quality refractory lining products. Rongsheng manufacturer has won the trust of customers in more than 60 countries around the world. For example, etc. Rongsheng not only sells magnesia-carbon bricks but also sells magnesia series refractories, siliceous series refractories, alumina series refractories, etc. If there are customer needs, we can also customize refractory products for customers according to their specific needs. To learn more about Rongsheng manufacturers and get more quotes on refractory products, please contact us. We will provide you with services according to your specific needs.