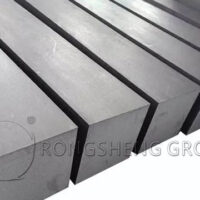

Graphite block is a graphite product commonly used in various industrial applications, also known as “widely used graphite block”. They are made of high-purity graphite, which has high thermal conductivity, low electrical resistance, and resistance to oxidation and corrosion. Based on experience, graphite block manufacturers know graphite blocks well. An introduction to graphite blocks, including their properties, manufacturing processes, and applications. For details, please contact the graphite block manufacturer.

Widely Used Graphite Block

Where are graphite blocks suitable for use? Graphite blocks have good chemical stability. Graphite is specially processed and has the characteristics of corrosion resistance, good thermal conductivity, and low permeability. Widely used in the production of heat exchangers, sound-absorbing tanks, condensing devices, combustion towers, absorption towers, coolers, heaters, filters, and pump configurations. It is widely used in the kerosene chemical industry, hydrometallurgy, acid and alkali production, synthetic fiber, papermaking, and other industrial sectors, and can save a lot of metal materials. Suitable for castings, aluminum castings, molding, and high-temperature metallurgical materials: Due to the small thermal expansion coefficient of graphite, it has the ability to change thermal shock and can be used as glass molds.

When using graphite black metal castings, the dimensions are accurate, the appearance is smooth, the yield is high, and no handling or light processing is required, thus saving a lot of metal. Powder metallurgy processes such as cemented carbide are often used to make molds and sinter porcelain boats from graphite materials. Monocrystalline silicon crystal growth crucibles, regional refining vessels, support fixtures, touch heaters, etc. are all made of high-purity graphite. Other graphite can also be vacuum-melted graphite insulation plates and base materials, high-temperature resistance furnace tubes, rods, plates, grids, and other components.

Conductive material industry: used in the electrical industry to manufacture electrodes, brushes, carbon rods, carbon tubes, mercury locator anodes, graphite gaskets, telephone parts, TV picture tube coatings, etc.

Wear-resistant lubricants: Graphite is often used as a lubricant in rigid industries. Lubricating oil often cannot be used under high-speed, high-temperature, and high-pressure conditions, while graphite wear-resistant materials can slide at high speeds at (a) 200~2000°C without lubricating oil. Piston cups, seals, and bearings made of graphite material are generally accepted in many configurations for conveying damping media that do not require lubricating oil. Graphite is also a good lubricant for many metal processing (wire drawing, tube drawing).

As a graphite block manufacturer specializing in machining, the graphite blocks produced by Rongsheng Manufacturer are used in various industries.

Graphite blocks are block-shaped graphite products cut from graphite. They can be processed into certain shapes and used in various industries. First of all, it is used in silicon carbide furnaces, graphitization furnaces, etc. Mainly used as lining materials in metallurgical furnaces and resistance furnaces. Second, it can be used to make various molds, hot pressing molds, static casting molds, centrifugal casting molds, die casting molds, etc. Third, it can be used as a cathode and anode material for metal electrolysis.

Characteristics of Widely Used Graphite Blocks

The characteristics of graphite blocks are inseparable from the high-quality performance and characteristics of the raw materials of graphite blocks. Being able to fully bring out these characteristics requires rigorous graphite block manufacturing processes. Therefore, graphite blocks are widely used in various industries.

Graphite blocks have high thermal conductivity, low electrical resistance, and high resistance to oxidation and corrosion. These properties make them ideal for high-temperature applications. Such as the production of steel, aluminum, and other non-ferrous metals. The high thermal conductivity of graphite blocks allows them to withstand high temperatures and distribute heat evenly. This property also makes them ideal for building high-temperature furnaces and other equipment that require efficient heat transfer.

The low resistance of graphite blocks makes them ideal for use in applications requiring high currents. This property also makes them ideal for electrolyzers used in the production of aluminum and other metals.

The high resistance to oxidation and corrosion of graphite blocks ensures that they have a long service life in harsh environments. This property also ensures that they do not contaminate the materials they come in contact with. Making it ideal for producing high-purity metals and other materials.

Graphite Block Manufacturing Process

Graphite block is made from a mixture of high-quality petroleum coke, needle coke, and coal tar pitch. The raw materials are crushed and ground into a fine powder, which is then mixed with coal tar pitch and formed into blocks using a molding process. The blocks are then baked at high temperatures to carbonize the coal tar pitch and convert the raw material into graphite. Finally, the resulting graphite block is machined to the required size and treated with a special coating to improve its electrical conductivity and resistance to oxidation.

Rongsheng Graphite Block Manufacturer

Graphite block is a versatile and important graphite product used in various industrial applications. They are characterized by high thermal conductivity, low electrical resistance, and high resistance to oxidation and corrosion. The manufacturing process of graphite blocks involves the use of high-quality raw materials such as petroleum coke and needle coke, which are converted into graphite through a baking process. Graphite blocks have a wide range of industrial applications, including the production of steel, aluminum, and other non-ferrous metals, as well as the production of high-purity metals and other materials. Rongsheng graphite block manufacturer is a powerful refractory brick manufacturer. We can provide high-quality graphite block products, graphite electrode products, etc. for the production of various industrial furnaces. Contact us to get free samples and quotes.