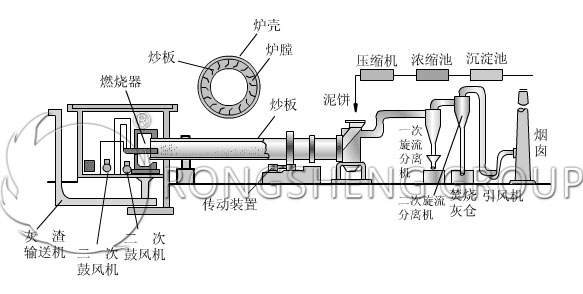

Cracks in the furnace wall of the waste incinerator will cause the refractory bricks to loosen and fall off; the temperature of the furnace wall support rises, or even turns red; the furnace wall leaks air; the furnace flame is ejected from the cracks. There are many reasons for cracks and cracks in furnace walls. When the newly built furnace wall and furnace arch are baked, due to the short drying time, too fast temperature rise, and deviation of the burning position, the furnace wall, and the furnace arch are heated too high, resulting in deformation, cracking, and collapse. Excessive heating and cooling in the furnace will cause the furnace wall and furnace arch to expand or contract suddenly, improperly reserved expansion joints, and too large brick joints will cause the furnace wall to crack.

When there are cracks and gaps in the furnace wall, what are the good remedies?

The conventional remedy is to use an asbestos rope to fill and coat the exterior with a layer of refractory cement, and asbestos powder mortar. Such fixes are often weak. When the furnace wall expands at a high temperature, or when the furnace is cooled and stopped, the blocking material is prone to loosening and falling off, cracking again, and the strength is not high. Is there a better way? The answer is yes. For cracks in the refractory furnace wall, the cracks can be potted with high temperature-resistant expansion glue. After the high-temperature resistant expansion glue is potted and sealed, the outer surface is sealed with a high temperature resistant inorganic adhesive. Good pointing skills can often do more with less.

When stitching, there are a few things to pay attention to.

1) The depth of the slit should be 6-8mm, and it should be uniform. The edges and corners of the exposed bricks should be squared, and the cracks and walls should be cleaned without leaving dry sand or mortar.

2) If there is local unevenness or slits in the ash joints, water should be used to moisten the wall before opening and pointing.

3) It is advisable to take the ash method for jointing. The concave depth is 3-4mm, and the ash joints should be uniform and smooth. Both the vertical and horizontal seams need to be cleaned without missing hooks.

The above methods can effectively prevent various adverse factors caused by poor boiler sealing. For example, with the negative pressure of the boiler, cold air will leak in from the gap of the furnace wall, reduce the furnace temperature and affect the combustion efficiency.

Build furnaces, repair furnaces, and buy refractory materials for incinerators. Rongsheng refractory material manufacturer is a powerful refractory material production and sales manufacturer with rich experience in the construction of refractory materials. Rongsheng has rich experience in solving the problem of kiln lining refractory. Customers who have purchased Rongsheng refractories also continue to purchase refractories from Rongsheng. If you are looking for a suitable refractory lining material, please contact us.