Silicon carbide refractory is a refractory material with silicon carbide as the main component. It has excellent high-temperature performance and chemical stability and is widely used in high-temperature industrial fields. The following are its main features and applications:

Key Features

Excellent High-Temperature Performance

- Silicon carbide has a melting point of up to 2700°C, high thermal conductivity (58.6 W/m·K), and a low coefficient of thermal expansion (4.4 × 10⁻⁶/°C). This gives it excellent thermal shock resistance and high-temperature strength, allowing it to withstand drastic temperature fluctuations and high-temperature shocks.

- It exhibits excellent stability in reducing atmospheres, but is susceptible to oxidation at high temperatures in oxidizing atmospheres, requiring surface coating or formulation optimization to enhance its oxidation resistance.

Strong Chemical Stability

- It exhibits excellent corrosion resistance to chemicals such as acids, alkalis, and salts, making it particularly suitable for environments exposed to molten metals and slag, such as blast furnace linings and crucibles for non-ferrous metal smelting.

Outstanding Wear Resistance

- Its hardness is second only to diamond, and its wear resistance is 5-20 times that of cast iron and rubber. It is commonly used for lining components such as wear-resistant pipes, impellers, and pump chambers.

Applications

Metallurgical Industry

- Used as lining material for key areas such as blast furnace tuyere, inner wall, and ceramic cups, as well as the bottom material for aluminum electrolytic cells.

- Used as lining material for blast furnace tapping channels, linings for hot metal pre-treatment units, and linings for cupolas and induction furnaces.

Ceramic Industry

- Used as kiln furniture materials, such as roof panels, pillars, and saggers, it improves firing efficiency and product quality.

Chemical Industry

- Used as lining material for oil and gas generators, petroleum gasifiers, and desulfurization furnaces, resisting chemical corrosion and high-temperature erosion.

Environmental Protection

- Used as combustion chamber sidewall linings and boiler tube protective linings for waste incinerators, utilizing its high thermal conductivity and wear resistance.

Preparation and Classification

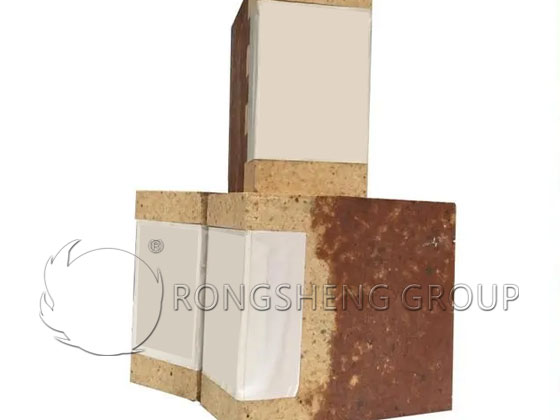

- Shaped refractories include oxide-bonded silicon carbide, nitride-bonded silicon carbide, and self-bonded silicon carbide. These materials differ significantly in performance based on the type of bonding phase.

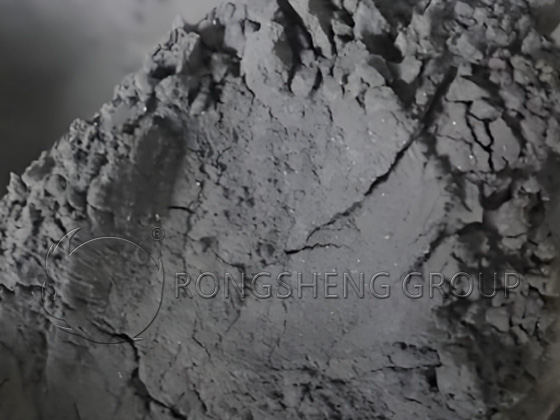

- Unshaped refractories, such as silicon carbide castables, are commonly used in blast furnace tapholes and cement kiln preheater linings. Silicon carbide is added to improve slag resistance and thermal shock stability.

Notes

- Silicon carbide is susceptible to oxidation in high-temperature oxidizing atmospheres and requires coating or formulation optimization to enhance its oxidation resistance.

- Different bonding phases (such as silicon nitride bonding and silicate bonding) significantly affect the material’s thermal shock resistance and oxidation resistance and should be selected based on the operating environment.

Silicon carbide refractory materials, due to their unique properties, have become an indispensable key material in high-temperature industries. Rongsheng Refractory Factory supplies high-quality silicon carbide refractory and carborundum brick. Contact Rongsheng for free samples and quotes.

Why Must Silicon Carbide Refractory Mortar be Used for Silicon Carbide Bricks?

Mullite-silicon carbide refractory bricks (or mullite-silicon carbide bricks) boast excellent wear resistance and thermal shock resistance and are widely used in the transition zone of cement rotary kilns. Currently, mullite-silicon carbide bricks are primarily produced from high-alumina bauxite with an alumina content of over 85% and silicon carbide, which are then machine-pressed and fired at high temperatures.

In recent years, cement rotary kilns have utilized waste and household garbage as fuel or raw materials for cement production, achieving a “resource-based, volume-reducing” approach to waste management and representing a future development direction for the cement industry. However, the harmful alkaline oxides in these alternative energy sources form gaseous substances during combustion. These gases accumulate within the cement rotary kiln over time, exacerbating vapor-phase erosion of the kiln lining’s refractory materials. For example, K(g) reacts with the mullite phase and corundum phase in silica-mudstone bricks through chemical reactions of formulas (1) to (3), forming nepheline (KAlSiO4) and leucite (KAlSi2O6), accompanied by a large volume expansion, which leads to the peeling and damage of silica-mudstone bricks.

2K(g) + 2Al6Si2O13 (s) + CO(g) =====2KAlSiO4 (s) + C(s) + 2SiO2 (s) + 5Al2O3 (s) (1)

2K(g) + 2Al6Si2O13 (s) + CO(g) =====2KAlSi2O6 (s) + C(s) + 5Al2O3 (s) (2)

2K(g) + 2KAlSi2O6 (s) + Al2O3 (s) + CO(g) =====4KAlSiO4 (s) + C(s) (3)

To improve the resistance of silica-molybdenum bricks to alkali vapor corrosion, improvements are generally made to their structure and composition. On the one hand, by introducing additives (such as Si, SiC, andalusite), the reactive volume expansion effect during the material preparation process is exploited to optimize the pore structure of the silica-molybdenum bricks, reduce the pore size, inhibit alkali vapor corrosion, and reduce its penetration into the material, thereby improving its resistance to alkali corrosion. On the other hand, by appropriately increasing the SiO2/Al2O3 (mass ratio) in the material matrix, a high-silica glass phase forms within the matrix during the preparation process. This phase readily transforms into a liquid phase upon contact with alkali, shifting the alkali corrosion behavior from direct reaction to dissolution-precipitation corrosion. This slows the corrosion process and eliminates significant volume expansion, significantly reducing the material’s corrosion rate.