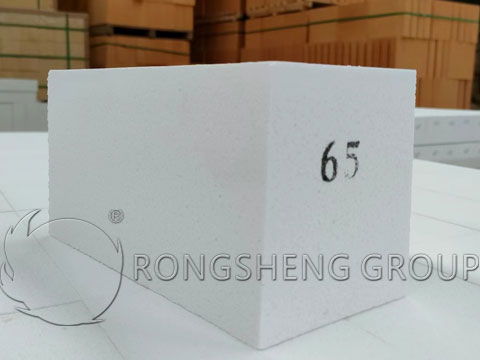

The performance and main application of thermal insulation silicon corundum bricks. It is characterized by embedding a specified area of thermal insulation material on the cold surface of the silicon corundum brick. The thermal insulation product material accounts for 60% of the cold state area, and the thermal conductivity of the thermal insulation material is only 0.11W/(m.k) at 500 degrees Celsius, effectively blocking heat transfer. Insulating silicon corundum bricks combine high strength, high wear resistance, erosion resistance, erosion resistance, thermal shock resistance, low thermal conductivity, energy saving, environmental protection, etc. It is widely used in the transition zone and cooling zone of large and medium-sized rotary kilns in cement, lime, and other building materials industries.

Performance characteristics of thermal insulation silicon corundum bricks

- Improve the strength, wear resistance, and corrosion resistance of the original products and prolong their service life.

- Improve the thermal shock stability of the product and overcome the cracking and peeling of lining bricks.

- Adjust the product line change rate. Make it closely combined with the equipment to avoid loosening the lining bricks and the phenomenon of falling bricks.

Characteristics and properties of thermal insulation silicon corundum bricks Applications

In order to meet the requirements of large and medium-sized rotary kilns and other thermal equipment in the cement, metallurgy, lime, and other product industries, the sections or parts with large temperature changes, high erosion, high wear, and high erosion, silicon corundum bricks came into being. Anti-scouring, anti-corrosion, no bricks falling off; reduce the number of maintenance, prolong the service life, reduce the temperature of the cylinder by more than 50 ℃; protect the safe operation of thermal equipment. Advantages of thermal insulation silicon corundum bricks applied in the rotary kiln.

- Improve the heat utilization efficiency of the rotary kiln, save energy consumption, and improve enterprise benefits.

- The overall performance is good, the effective use volume is larger than that of composite products, and the anti-wear period is long.

- Reduce heat emission and meet environmental protection requirements.

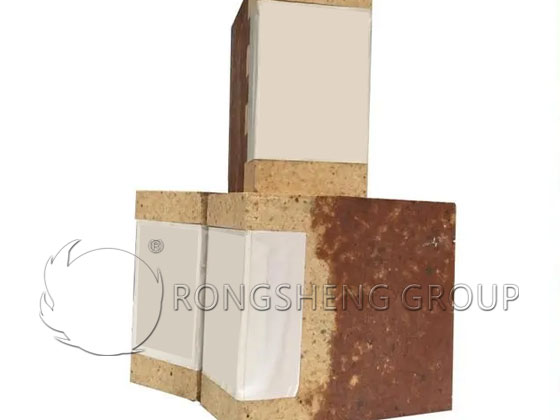

The difference between phosphate composite brick and silicon corundum brick

There are two biggest differences between phosphate composite bricks and silicon corundum bricks: one is the bulk density, and the other is the silicon carbide content.

Phosphate composite bricks are suitable for use in kiln linings in alkaline atmospheres and are mostly used in lime kiln linings. The production process of phosphate composite brick and phosphate brick is basically the same, the difference is that different proportions of silicon carbide are added to the raw material, so it is called phosphate composite brick. The biggest difference between composite bricks and thermal insulation silicon corundum bricks is that in the process ratio of composite bricks, a large proportion of silicon carbide is added. The large proportion of silicon carbide can enhance the wear resistance and erosion resistance of the brick, and the service life of the kiln lining is longer.

Regardless of the process ratio, the greater the bulk density, the higher the quality of the raw materials used, and the higher the aluminum content. Phosphate refractory bricks generally use high-iron or low-iron bauxite as the main raw material, and the addition of silicon carbide depends on the degree of wear resistance and corrosion resistance of different furnace linings. The higher the bulk density, the better the quality of the brick and the better the wear resistance.

However, if the bulk density is high, the overall weight of the kiln lining will increase. Therefore, some manufacturers use lightweight silicon corundum bricks, which not only ensure the light weight of the kiln body but also have a good heat preservation effect and save fuel. However, the production cost of light silicon corundum bricks is higher than that of dense silicon corundum bricks. And there will be bricks falling and peeling off.

Which brick type to choose scientifically depends on the size of the lining of the kiln. If the lining is too small, phosphate bricks can be used, and for medium-sized linings, phosphate composite bricks can be used. For industrial furnaces with large kiln lining, silicon corundum bricks will be selected. If there is a weight requirement for the kiln, lightweight silicon corundum bricks will also be used as the lining.

In short, whether it is phosphate composite brick or thermal insulation silicon corundum bricks, they are all sintered at low temperatures, and the sintering temperature does not exceed 600 °C. This is also the sintering difference between chemically bonded refractory bricks and other high-temperature bricks. The lining material is selected according to different lining atmospheres and different lining sizes.

Low Silica Corundum Brick

Low-silica corundum brick refers to high-purity corundum refractory products with SiO2 content less than 0.2%. When used in high temperature, high pressure, and strong reducing atmosphere. Impurities such as SiO2, Fe2O3, and Na2O in corundum products are easily reduced and migrated, which reduces the high-temperature performance of the material and causes structural damage. SiO2 can be reduced to gaseous SiO2 and then oxidized to SiO2 under certain temperature conditions to block the pipeline. Therefore, high-purity and low-silica corundum bricks are required.

Performance of low silica corundum brick

It has good high-temperature corrosion resistance and high-temperature stability in a strong reducing atmosphere. Physical and chemical properties of a representative low-silicon corundum brick. Al2O3 99.42%, SiO2 0.16%, Fe2O3 0.08%, apparent porosity 17%, density 3.27g/cm3. The compressive strength at room temperature is 98.7MPa, and the flexural strength at high temperature (1250°C) is 9.6MPa. Heat shrinkage rate (1600℃·3h) 0.1%-0.2%. Thermal shock resistance (1000°C, air cooling) is greater than 50 times.

The manufacturing process of low-silica corundum brick

Use high-purity low-silica fused or sintered corundum sand as the aggregate, and use α-Al2O3 fine powder with a particle size of less than 5 μm. Add materials in a certain order, mix them well, and press them into shape with a friction brick press or a hydraulic brick press. The green body is dried until the water content is less than 0.2% and fired at 1800°C according to the firing system.

Process points of low silica corundum brick

In order to produce high-purity low-silica corundum bricks, the raw materials used are required to have high purity: Al2O3>99%, and SiO2<0.2%. The preparation of fused corundum sand or sintered corundum sand and alumina fine powder also uses high-purity and low-silica raw materials. During the preparation process, the mixing of impurities should be avoided as much as possible, and the mechanical iron entering during the crushing process should be removed.

Reducing the critical particle size and increasing the amount of fine powder can improve the density and strength of the product. However, if the amount of fine powder is too much, the shrinkage of the product will increase.

Application of low silica corundum brick

It is mainly used as the lining material of residual oil gasification furnaces in the petrochemical industry. Working under the conditions of high temperature, high pressure, and high-speed airflow, its service life can be extended.

Rongsheng Refractory Material Manufacturer

Rongsheng refractory material manufacturer is a refractory material manufacturer and sales company with rich production and sales experience. Our refractory products have been sold to more than 70 countries and regions all over the world. Moreover, our technical team can eliminate the production needs of industrial furnaces and provide solutions for refractory lining materials for industrial furnaces. At the same time, we also provide the design and construction of insulation layer refractory materials for various rotary kilns, so as to save production energy and cost for customers to the greatest extent. Contact us for free solutions and quotes.