Andalusite decomposes to form a needle-like or columnar mullite phase and quartz phase at a high temperature of 1350~1550℃, resulting in 3%~5% irreversible expansion. On the one hand, the micro-expansion produced in the product can improve the microstructure and improve its physical properties such as thermal shock resistance. On the other hand, the mullite generated in situ is interspersed or dispersed between the particles, so that the product has excellent performance. Such as higher softening point under load, better creep resistance, etc. Therefore, andalusite is widely used in the field of Al2O3-SiO2 refractories. However, for different aluminum-silicon refractory castables, the introduction of andalusite has different performance improvements. At the same time, the introduction method of andalusite also determines its improvement effect to a large extent. Next, Rongsheng refractory manufacturer will take you to understand andalusite refractory castable and its properties. Get a free quote.

Andalusite Refractory Castable

The main raw materials used in andalusite refractory castables are South African andalusite, special grade alumina, tabular corundum, a-AL2O3 powder, SiO2 powder, and A80 cement. After the sample is proportioned, add an appropriate amount of water to stir evenly, and then vibrate casting to form a sample of 40mmX40mmX160mm. Demoulding after 24h standard curing. Dry in the air at 110°C for 24h. It is fired in a high-temperature electric furnace at 1200℃, 1300℃, 1400℃, and 1500℃ for 5h.

Application Characteristics of Andalusite Refractory Castables

Andalusite refractory castable, due to the aggregate and particle size characteristics of the matrix itself, has very good slag resistance and thermal shock resistance. Especially, the linear change rate is smaller and the volume is more stable under high temperature.

The volume expansion of andalusite refractory castable decreases after heat treatment, and the linear rate of change decreases. The particle size of the andalusite aggregate can adjust the thermal expansion rate, and the volume shrinkage produced during long-term use is small. Thereby improving the volume stability of the castable.

The thermal shock properties of andalusite castables are due to the fact that the added andalusite decomposes at high temperatures to form a structure of mullite and silica-rich glass phases. The silica-rich glass phase produced by andalusite fills the pores and enhances the effect of promoting sintering so that the castable structure slows down the thermal stress during the thermal shock process. Improve the thermal shock stability of the castable.

Andalusite refractory castable has a thin oxide layer of andalusite aggregate. The introduction of andalusite aggregate greatly improves the oxidation resistance of castables. This is because the silica-rich glass phase produced by the decomposition of andalusite fills the pores and prevents oxygen from entering the castable. With the reduction of andalusite aggregate particle size and the increase of sintering temperature, the amount of silica-rich glass phase is increased, the porosity is reduced, and the oxidation resistance is stronger.

The strength of andalusite refractory castable is also due to the introduction of andalusite aggregate. Andalusite aggregate will increase in strength after high temperature. Because andalusite is decomposed to produce secondary mullite, the secondary mullite promotes the combination of andalusite aggregate with other raw materials in the castable and improves the high-temperature strength of the castable. With the addition of andalusite aggregate in the castable, the SiO2 produced after the decomposition of andalusite increases, and the amount of secondary mullite produced also increases, so the high-temperature strength of the castable is further improved.

It can be seen from the above that the high-temperature resistance and thermal shock resistance of andalusite refractory castables are very good. Therefore, andalusite castables are selected when the corrosion is large at high temperatures.

Advantages of Andalusite Refractory Castable

(1) Andalusite is introduced into the thermal shock resistant castable in the form of a matrix. At high temperatures, mullite reaction and secondary mulliteification are more adequate. It helps to improve the bulk density of the sample and the high-temperature strength of the sample above 1300℃. Reduce the linear expansion rate of the sample.

(2) Among the refractory castables configured with andalusite to super-grade aggregates, the decomposition of andalusite and the secondary multimerization is relatively easy. The produced mullite closely connects the bauxite clinker, which more effectively improves the physical properties of the sample.

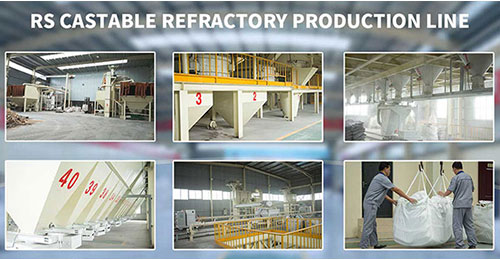

Rongsheng Refractory Castable Manufacturer

Rongsheng is a refractory castable manufacturer with rich experience in production and sales. Rongsheng’s refractory bricks and monolithic refractories products have been sold to more than 60 countries around the world. For example, Thailand, UAE, Turkey, Kuwait, South Africa, Malaysia, Vietnam, Netherlands, Philippines, Singapore, Egypt, Russia, etc. Moreover, Rongsheng’s refractory material-technical team specializes in making suggestions for refractory lining products, aiming to provide customers with high-quality refractory products and save production costs. In addition, as a manufacturer with an advanced fully automatic refractory castable production line, Rongsheng produces 80,000 tons of monolithic refractory products per year. Learn about Rongsheng refractory manufacturers and get the price of refractory materials for free. Please contact us, we will provide you with services according to your specific needs.