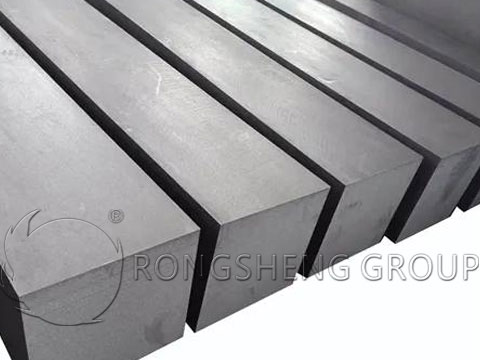

Graphite Blocks for Sale belong to neutral refractory materials, which are resistant to erosion of the slag or solvent from acid and alkali materials, as well as other chemical substances. Graphite refractory block is featured with erosion resistance, slag resistance, low thermal expansion coefficient, good heat conductivity, and good thermal shock resistance. Graphite blocks can be used in the lining of a reactive tank, storage tank, and the autoclave used in the chemical industry. Besides, blocks of graphite can be used in the bottom of the blast furnace.

Graphite Blocks Manufacturing Process

Carbon graphite blocks are made of carbon graphite materials. They are manufactured in the process of graphitization in the electric furnace at high temperature about 2500-2800℃. The main raw material of the graphite blocks is calcined anthracite, and the binder is pitch. Such products are produced through forming, high temperature baking, and final precision machining.

Graphite Refractory Bricks Properties

Compared with other refractory bricks, graphite bricks have advantages of the follows:

Graphite bricks save energy and fuels, because of the performances of good thermal conductivity, rapid heat transfer, and uniform heating. In addition, graphite bricks are environmental friendly, with no radioactivity pollute, because of the strong anti-oxidation and reduction performances at the temperature 3000℃ below, especially in the neutral mediums. Besides, such bricks are excellent in chemical properties and erosion resistance, for the features of low porosity, anti-scouring, and anti-wear performance. As for the compressibility, graphite brick is featured with good compressibility, because of the low hardness of the graphite.

Rongsheng Properties

- Excellent in chemical properties and erosion resistance

- Good thermal properties and thermal conductivity

- Environmental friendly

- Rapid heat transfer, and uniform heating

- High refractoriness and good thermal shock resistance

- High melting point, about 3700℃

Besides the chemical and physical properties, graphite brick is also featured with excellent thermal properties, such as high refractoriness and good thermal shock resistance, so it will not crack because of the temperature change. Such a product has a very high melting point, about 3700℃, and with the rise of the temperature, the intensity of the graphite increases too. Moreover, it has low thermal expansion coefficient, so it has stable performance and strong durability.

In addition to the properties of the brick itself, it also has other advantages during the construction, such as pollution-free, easy cleaning, excellent curing process, and long-term usage, etc.

Graphite Blocks Uses

For the properties above, graphite blocks are widely used in various industries, take the following parts for example:

- Autoclave

- Acid tank

- Plating bath

- Storage tank

- Reactive tank

- Alumina electrolysis cell

- Blast furnace, etc.

Graphite Blocks Suppliers

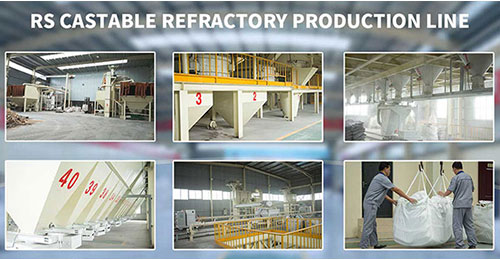

You can buy graphite block from graphite block suppliers, such as RS. It is a comprehensive enterprise specialized in refractory materials for more than 20 years. It has a series of refractories used in various industrial kilns or furnaces.

It has perfect production equipment and testing instrument, and passed ISO9001: 2008 quality system certification, environmental management system certification, and occupational health and safety management system certification.

Products

- Refractory bricks: high alumina bricks, chrome bricks, carbon bricks, magnesia bricks, fireclay bricks, etc.

- Monolithic refractories: calcined bauxite aggregate, high alumina cement, refractory castable, etc.

- Insulation materials: ceramic fiberboard, insulation blanket, refractory ropes and refractory balls, etc.

There are about 1262 employees, including senior technical personnel 65, high-tech workers 80 and complete physical and chemical testing equipment and advanced detection methods. The credit rating is AAA grade, and the economic indicators and the enterprise technical force, namely the scale keeps the leading position in the domestic industry.

With superior quality and good credit, RS has gained the honor of advanced enterprise given by the Industrial and Commercial Bureau of Henan Province. In order to adapt the market, the company has established long-term stable technical cooperation with colleges and universities, and now it has been a high-tech and fast growth enterprise.

Rongsheng Refractory Manufacturer

- Scale: 1262 employees, including senior technical personnel 65, high-tech workers 80

- Credit: AAA

- Quality: Passed ISO9001: 2008 quality system certification

- Business purpose: honesty, respectful, innovation, and dedication

- Customers: Japan, Indonesia, Iran, Kazakhstan, Vietnam, etc.

Professional sales and after-sales service team: they offer consumers the best all-round services in applications, construction and installation, operation and technical training, etc. Rongsheng has established cooperative relations with multiple scientific research institutes, and graphite blocks for sale from RS have been exported to Japan, Indonesia, Iran, Kazakhstan, Vietnam, etc.

Rongsheng has always been adhering to the business purpose of honesty, respect, innovation, and dedication. It will persist the strategic developing road based on quality and cheap to establish its own brand. By scientific management, sound customer information management systems, and abundant products, Rongsheng provides satisfactory, timely, and efficient service to the consumers.