Currently, magnesia-chromium or magnesia-alumina refractory bricks produced by a certain refractory material manufacturer all require salt immersion treatment. The salt immersion treatment time is generally 1-5 hours, after which the bricks are placed in a drying kiln for drying. This is mainly to improve the erosion resistance of the magnesia refractory bricks, while also extending their service life and reducing their operating costs. However, the prolonged salt immersion process introduces a large amount of moisture into the magnesia refractory bricks. If this moisture is not removed in time, it will negatively impact the performance of the magnesia refractory bricks. Therefore, the subsequent kiln drying process plays a crucial role in stabilizing the performance of the magnesia refractory bricks.

Problems to be Solved in Salt Impregnation Heat Treatment Kilns for Magnesia Refractory Bricks

Basic Situation of Magnesia Refractory Brick Production

Magnesia refractory bricks are alkaline refractory materials made from magnesite as raw material, with periclase as the main crystalline phase and a w(MgO) content of 80%~85% or higher. Magnesia refractory bricks have a refractoriness exceeding 2000℃ and a load softening temperature of 1550~1650℃, while also exhibiting excellent erosion resistance. They are widely used in areas severely corroded by high-temperature alkaline slag, such as steel ladle linings, cement rotary kiln firing zones, and secondary refining furnaces. Refractory material manufacturers use a 1000t friction brick press to produce magnesia refractory bricks, which are then salt-impregnated for 2.5 hours after high-temperature firing, and then sent to a drying kiln for drying.

During prolonged salt immersion treatment, the magnesium oxide in these magnesia refractory bricks readily reacts with water to form magnesium hydroxide:

MgO + H₂O = Mg(OH)₂

From the production perspective of refractory material manufacturers, after hydration, the surface of magnesia refractory bricks exhibits bulges of varying sizes, a white bloom, a more porous structure, and star-shaped cracks. If the hydration reaction is severe, the refractory bricks will eventually pulverize completely, rendering them unusable. To effectively prevent hydration, after a 2.53-hour salt immersion treatment, the magnesia refractory bricks are immediately sent to a heat treatment kiln for comprehensive heat treatment. This timely evaporation of moisture from the salt prevents the hydration reaction and ensures the performance of the magnesia refractory bricks.

Analysis of Problems to be Solved in Salt Impregnation Heat Treatment Kilns for Magnesia Refractory Bricks

Refractory material manufacturers need to effectively address the following issues in the salt impregnation heat treatment kilns for magnesia refractory bricks:

1) Experiments show that the hydration rate of magnesia refractory bricks accelerates in the temperature range of 85-115℃. Therefore, when magnesia refractory bricks are fed into the heat treatment kiln, the area near the kiln inlet often experiences more severe hydration reactions due to the lower temperature. Thus, it is required that the magnesia refractory brick blanks near the kiln inlet be removed from the 85-115℃ temperature range as soon as possible during heat treatment.

2) In the heat treatment kiln, when the temperature reaches 195℃, it is required to hold at that temperature for 5 hours. However, during the kiln loading and unloading processes, the opening of the kiln door allows outside air to enter, causing significant fluctuations in the kiln’s holding temperature and pressure, affecting the quality of the magnesia refractory bricks.

3) The location of magnesia refractory bricks in the heat treatment kiln will result in different hot air volumes. Therefore, the heat treatment kiln must be designed in zones and the hot air volume must be controlled in zones to ensure the rationality and reliability of the temperature distribution in the kiln.

Design of a Heat Treatment Kiln for Magnesia Salt-Immersed Refractory Bricks

Technical Scheme Analysis of the Heat Treatment Kiln Design

Addressing the problems existing in the heat treatment kilns for magnesia salt-immersed refractory bricks manufactured by refractory material manufacturers, technical solutions including inlet and outlet preparation chambers, zoned airflow control, and a hot air circulation device were designed. This effectively ensures that the heat treatment process of the kiln meets the requirements for heat treatment of salt-immersed magnesia refractory bricks.

1) An inlet preparation chamber is set at the front of the heat treatment kiln, and an outlet preparation chamber is set at the rear. When it is necessary to open the inlet or outlet kiln door, the inlet or outlet preparation chamber is closed in advance. This operation can effectively prevent external air from entering the heat treatment kiln, avoiding any impact on the temperature and pressure inside the kiln.

2) Several carriages are set inside the heat treatment kiln body, with hot air inlets and exhaust gas outlets above the carriages. A hot air inlet side jacket is set on the left side of the kiln body, and an exhaust gas outlet side jacket is set on the right side of the kiln body. The left and right sides are equipped with partitions, dividing the air intake and exhaust into three zones. Each zone’s air intake and exhaust can be independently adjusted, preventing mutual interference. A blower delivers hot air to the hot air inlet, which is then directed into the heat treatment kiln via an adjustable baffle plate. The magnesia-impregnated refractory bricks inside the kiln are treated according to the thermal regime.

3) Multiple circulating fans are installed at the top of the heat treatment kiln to effectively ensure the uniformity and reliability of the temperature throughout the kiln.

4) The hot air for this heat treatment kiln is supplied by a separate hot blast stove.

Kiln Configuration and Heat Treatment Process

Kiln Configuration

Design of a heat treatment kiln for magnesia-impregnated salt refractory bricks. It mainly consists of an inlet preparation chamber, an outlet preparation chamber, the kiln body, kiln doors, a blower, an exhaust fan, and a circulating fan.

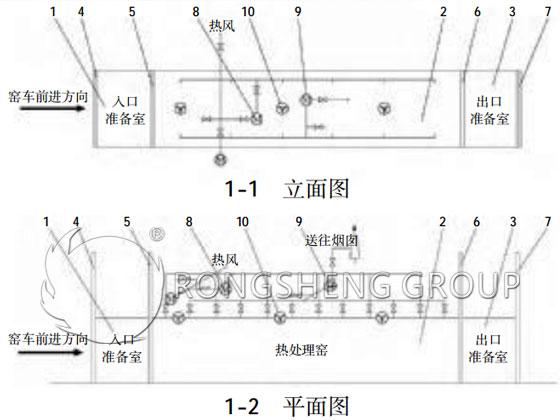

1—Inlet preparation chamber; 2—Kiln body; 3—Outlet preparation chamber; 4~7—Kiln doors (No. 1, 2, 3, and 4 respectively); 8—Blower; 9—Exhaust fan; 10—Circulating fan

Figure 1: Schematic diagram of the heat treatment kiln design for magnesia-impregnated salt refractory bricks.

Kiln Heat Treatment Process

Kiln heat treatment process analysis: Kiln car passes through kiln door No. 1 → arrives at the inlet preparation chamber → closes kiln door No. 1 and kiln door No. 4 → opens kiln door No. 2 and kiln door No. 3 → kiln car in the inlet preparation chamber is pushed into the kiln body → closes kiln door No. 2 → the last kiln car in the kiln body is towed to the outlet preparation chamber → closes kiln door No. 3 → open kiln door No. 1 and kiln door No. 4 → push the kiln car into the inlet preparation chamber and tow the kiln car out of the outlet preparation chamber.

Kiln Characteristics Analysis

Characteristics analysis of this magnesia salt-impregnated refractory brick heat treatment kiln:

1) The moisture content of the magnesia salt-impregnated refractory brick material varies in different areas within the heat treatment kiln, resulting in different requirements for hot air volume and drying speed. By implementing a zoned control mode for temperature and air volume in different areas of the heat treatment kiln, the drying speed of the magnesia salt-impregnated refractory brick material can be controlled. This effectively solves the problem of easy hydration of the magnesia salt-impregnated refractory brick material at the inlet kiln door location, a problem previously encountered by this enterprise.

2) A circulating fan is installed at the top of the heat treatment kiln body, which effectively adjusts the temperature uniformity between the upper and lower parts of the kiln, minimizing temperature differences within the kiln. This ensures the heat treatment process of the magnesia-impregnated refractory bricks, thereby guaranteeing the quality of the refractory bricks.

3) By setting up inlet and outlet preparation chambers in the heat treatment kiln, the kiln door lifting sequence can be effectively controlled. This effectively prevents temperature and pressure fluctuations caused by air entering and exiting the kiln car.

4) The heat treatment kiln operates under negative pressure, completing the entire physicochemical process of the magnesia-impregnated refractory bricks. This effectively improves the conditions inside the kiln, resulting in significant energy savings, reduced consumption, and environmental protection.

5) The heat treatment kiln is controlled by a PLC. The application of the PLC control system enables fully automated operation of the mechanical equipment within the heat treatment kiln and fully automatic adjustment of the kiln’s thermal regime.

Effect Analysis

The heat treatment kiln for magnesia refractory bricks, manufactured by a refractory material manufacturer, was designed according to the above technical scheme, including kiln configuration and heat treatment process, and then put into practical application. The application results show that after the heat treatment kiln design was completed, the drying process of the magnesia refractory bricks after salt impregnation was effective. This heat treatment process effectively and promptly removed the moisture from the magnesia refractory bricks after salt impregnation. There was virtually no hydration reaction, and no blistering, white bloom, or star-shaped cracks occurred on the surface. Testing showed that the magnesia refractory bricks exhibited good erosion resistance, stabilizing their performance.

After salt impregnation, the magnesia refractory bricks need to be dried in a heat treatment kiln to remove the moisture. Targeted designs were implemented for the inlet and outlet preparation chambers, hot air circulation device, and hot air volume zoned PLC control system. This effectively ensured the required thermal regime of the heat treatment kiln after salt impregnation of the magnesia refractory bricks, resulting in ideal practical application results. The heat treatment kiln adopts a PLC control system, which can realize the fully automated operation of mechanical equipment inside the heat treatment kiln and the fully automatic adjustment of the thermal regime of the heat treatment kiln, resulting in significant energy saving, consumption reduction and environmental protection effects.