The High-Temperature Micro-nano Insulation Bricks products can solve the need for thermal insulation lining of the wall and bottom of various large furnaces, and the working temperature can be from 600℃ to 1400℃. Its outstanding features are low Fe2O3 content, high heat preservation, and small deformation. So it is a wide range of applications. It is obvious that the High-Temperature Micro-nano Insulation Bricks can meet the requirements of energy saving and environmental protection for various industrial furnaces. Better help enterprises save fuel costs in production.

Performance Advantages and Features of Micro-nano Insulation Bricks

- (a) Low thermal conductivity: With low thermal conductivity, it has a good heat insulation effect and can make the furnace wall thickness thinner under the same temperature condition, thus saving more cost.

- (b) Low heat capacity: Due to its ultra-light bulk density and low thermal conductivity, the New High-Temperature Micro-nano Insulation Bricks accumulate less heat inside, making them more energy efficient.

- (c) Good stability: With very low iron oxide and alkali metal content, its stability is better within the specified service temperature.

- (d) High strength: Its strength at normal and high temperatures is higher than other products with the same bulk density at the same temperature.

- (e) Low size tolerance: The size tolerance is within 0.05mm, and the dimensions can be customized according to customer requirements.

Indicators High-Temperature Micro-nano Insulation Bricks Can Achieve

| Items | Index | ||||

| Model | RS-WNM0.25 | RS-WNM0.35 | RS-WNM0.4 | RS-WNM0.45 | RS-WNM0.5 |

| BD,g/cm3 | 0.25 | 0.35 | 0.4 | 0.45 | 0.5 |

| CCS, MPa | ≥0.5 | ≥0.6 | ≥0.8 | ≥1.0 | ≥2.2 |

| TC,W/(m.K) | ≤0.1 | ≤0.105 | ≤0.110 | ≤0.115 | ≤0.119 |

| PLC,% | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

| 600℃*12h | 900℃*12h | 1000℃*12h | 1050℃*12h | 1050℃*12h | |

| Fe2O3,% | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

High-Temperature Micro-nano Insulation Bricks Applications

The High-Temperature Micro-nano Insulation Bricks can be used as a thermal insulation layer of refractory materials, and the application includes all kinds of industrial furnaces, hot blast furnaces, heating furnaces, smelting furnaces, flue pipes, hot air ducts, and other heating and heat-generating parts. It can replace some lightweight insulating bricks series as long as it is under the working temperature and working conditions it can withstand. Moreover, it can achieve high dimensional accuracy, closed pores, and good thermal insulation performance.

Micro-nano Insulating Bricks For Roller kilns, Tunnel kilns

- Application positions: Furnace walls and bottom insulation layer of the ceramic roller kiln.

- Replace the following insulation bricks: Lightweight clay brick, high alumina insulating brick, and mullite insulating bricks.

- Advantages: not easy to shrink, not easy to pulverize, performance not easy to decay, and more cost-effective.

Micro-nano Insulating Bricks For Large Hot Air Ducts

- Application positions: Insulation layer of a large hot air duct.

- Replace the following insulation bricks: Lightweight clay bricks, high alumina poly-light bricks.

- Advantages: lower outside wall temperature, more energy efficiency, lighter weight of thermal equipment, and more cost-effectiveness.

High-Temperature Micro-nano Insulation Bricks Applications Advantages

Our technical department announced some of its performance indicators: the bulk density can be ≤ 0.4 g/cm3 and thermal conductivity can be ≤ 0.11. It can work in the temperature range of 600-1400°C. Due to these advantages, the insulating bricks’ application advantages are as follows:

- Reduce the outer wall temperature of high-temperature industrial kiln

The actual measured data when the wall thickness of two different materials is 300mm, the data are compared as follows:

- With Rongsheng lightweight thermal insulation block bricks, the temperature of the outer wall is 70°C (low);

- With ordinary lightweight heat-insulating bricks, the outside wall temperature is 83°C (high).

- The difference of outside wall temperature: 13°C↓.

Conclusion: Rongsheng’s High-Temperature Micro-nano Insulation Bricks reduce the outer wall temperature by 18.57%↓.

- Reduce the weight of the furnace body of the high-temperature industrial kiln

The actual measured data, when the temperature of the outside wall reaches 80°C, the data are compared as follows:

- Using Rongsheng High-Temperature Micro-nano Insulation Bricks, only 210mm thick (thin) is needed;

- Using ordinary lightweight thermal insulation bricks, 330mm thick (thick) is needed.

- The difference of wall thickness: 120mm↓.

Conclusion: Rongsheng light-weight thermal insulation bricks reduce the thickness of the furnace wall by 57.14%↓.

Moreover, in the compressive strength and shrinkage of the refractory insulation materials product, our High-Temperature Micro-nano Insulation Bricks products are also very advantageous.

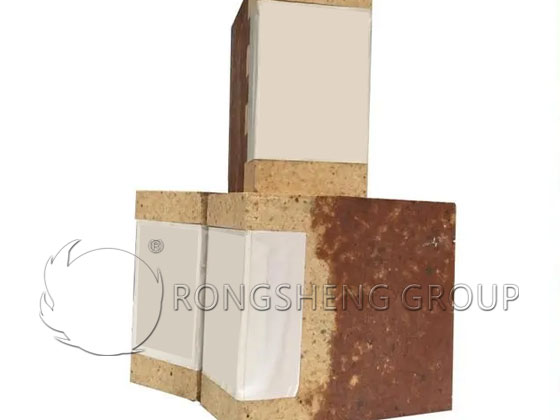

From the picture, we can visually experience the advantages of our new thermal insulation bricks, High-Temperature Micro-nano Insulating Bricks. Through the experimental comparison, comparing with clay insulation bricks under the same experimental conditions, it can be found that our new high-temperature insulation brick product has a complete appearance and almost no change in size.

Rongsheng Refractory Insulation Bricks Manufacturer

Rongsheng Refractory Insulation Bricks Manufacturer has been working hard to provide better insulating refractory materials for furnaces linings. Finally, we achieved a breakthrough in refractory insulation materials. Its high performance-price ratio will make it widely used in the insulation layer of more and more high-temperature industrial furnaces. Effectively reduce the temperature of the outer wall of the kiln, saving production energy and fuel costs. Let Rongsheng help you better with the high-temp insulating bricks. For more info on High-Temperature Micro-nano Insulation Bricks, please leave a message or contact us directly. WhatsApp: +86 18538312977, Email: Sales@rongshengrefractory.com.