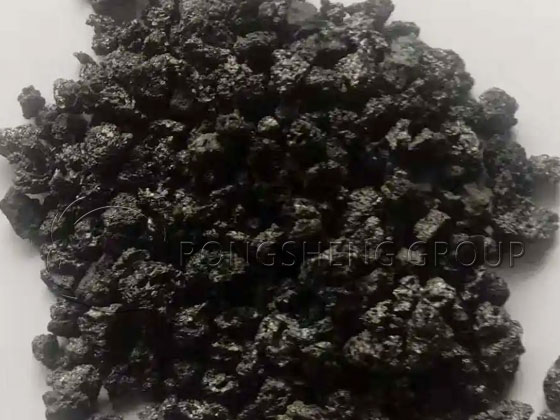

Petroleum coke recarburizer is a substance with a high carbon content and can be used as a Carbonine(carburant Material) in the steel smelting process. Its main component is carbon, but it is not pure carbon. Instead, it is mainly composed of carbon, mixed with a small amount of impurities and other elements.

Production Technology of Petroleum Coke Carburizer

The raw material of petroleum coke carburizer is mainly petroleum coke. In addition, there are charcoal, coal-based charcoal, coke, graphite, raw petroleum coke, etc. Different manufacturers may have different raw materials and production processes for producing petroleum coke carburizers. Some carburizers may use graphite electrodes, graphitized oil coke, etc. as raw materials. In short, there are many types of raw materials for petroleum coke carburizers, depending on the manufacturer and production process.

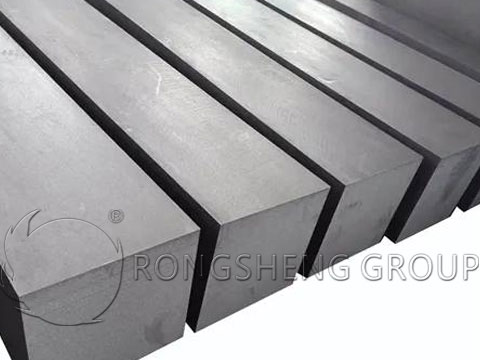

Petroleum coke is black solid coke produced by cracking petroleum through a pressure reducing device. The main components are amorphous carbon bodies, polymer carbides, and carbon bodies with a needle-like or granular structure of medium and small graphite crystals. Its appearance is a black or dark gray honeycomb structure, and the pores in the coke block are mostly oval and interconnected. Petroleum coke has a high carbon-to-hydrogen ratio of 18 to 24. The relative density is 0.9~1.1. The ash content is 0.1%~1.2%, and the volatile matter is 3%~16%.

Production Process of Petroleum Coke Carburizer

- Coke oven calcination.

Petroleum coke is sent to the coke oven for high-temperature calcination to increase the fixed carbon content of the petroleum coke and reduce impurities.

- Crushing and screening.

The calcined petroleum coke will become more brittle and hard. Therefore, it needs to be crushed into the required particle size through crushing equipment and screened. Remove particles that do not meet requirements.

- Graphitization treatment.

The crushed and screened petroleum coke is sent to the graphitization furnace for graphitization treatment. Graphitization furnaces usually use resistance heating. Through high-temperature heating, the petroleum coke undergoes structural changes to form a graphite structure, and its fixed carbon content is further increased.

What are the Advantages of Petroleum Coke Carburizer Compared to Other Carburizers?

- Less impurities.

Petroleum coke carburizer has undergone strict purification and processing during the preparation process. Therefore, its impurity content is lower and its purity is higher.

- The price is reasonable.

The price of petroleum coke carburizer is relatively reasonable and more economical than other carburizers.

- High absorption rate.

Petroleum coke carburizer has a high absorption rate. It can be utilized by steel mills faster, thereby improving the quality and production of steel.

- The effect is good.

Petroleum coke carburizer has good effect when used in steel materials, which can improve the hardness and strength of steel while reducing costs.

The Role of Petroleum Coke Carburizer in Steel Production

- Increase carbon content.

Petroleum coke carburizer contains higher carbon content. Adding an appropriate amount of petroleum coke carburizer during the steel smelting process can increase the carbon content in the molten steel. Thereby improving the strength, hardness, wear resistance and fatigue resistance of steel.

- Improve chemical composition.

The main component of petroleum coke carburizer is carbon, and it also contains a small amount of sulfur, phosphorus and other elements. During the steel smelting process, these elements can be added to the steel as alloying elements. Increase the number and purity of steel inclusions, thereby improving the brittleness and ductility of steel.

- Improve absorption rate.

The smaller the particle size of the petroleum coke carburizer, the faster its oxidation loss rate and dissolution and diffusion rate, and vice versa. In steel production, choosing the appropriate particle size of petroleum coke carburizer can increase its absorption rate, allowing more carbon elements to be absorbed by the steel. Thereby improving the quality and production of steel.

- Stabilize the production process.

In the steel production process, if too much petroleum coke carburizer is used, the carbon content in the molten steel will be too high, which will affect the performance of the steel. Therefore, controlling the amount of petroleum coke carburizer added is the key to ensuring the stability of steel production and the quality of steel products.

Applications of Petroleum Coke Carburizer in Other Aspects

Petroleum coke carburizer is an important material widely used in metallurgy, chemical industry, electric power, and other industries. Its uses and functions are diverse.

- In the metallurgical industry, petroleum coke carburizer can be used as a reducing agent in the steel production process. Used to reduce metal oxides and improve the purity and quality of metals. At the same time, it can also adjust the temperature and chemical reaction rate during the smelting process, making the smelting process more stable and efficient. In addition, petroleum coke carburizer can also be used as raw material for large cathode blocks, large carbon electrodes, large graphitized electrodes and high-performance electrode pastes.

- In the chemical industry, petroleum coke carburizer can be used as a catalyst or adsorbent to promote chemical reactions or separate and purify substances. For example, in petrochemical production, petroleum coke carburizer can be used in the reforming reaction in the catalytic cracking process. Improve the yield and quality of gasoline and liquefied gas. In addition, it can also be used as a reducing agent, casting recovery inoculant, refractory materials, etc. in the chemical industry.

- In the power industry, petroleum coke carburizer can be used as fuel to power power plants to provide stable heat and electricity. Compared with traditional coal, the combustion of petroleum coke carburizer produces less waste gas and waste residue. It has less impact on the environment and meets the needs of modern society for clean energy.

- Petroleum coke carburizer can also be used in aluminum electrolysis and electronic material preparation, as conductive materials and conductive fillers respectively. Promote the electrolysis reaction of aluminum and improve the conductive properties of the material.