The tunnel kiln wall is composed of a kiln wall body made of refractory materials and an external steel shell. The kiln wall insulation layer keeps the kiln shell at a low temperature and improves the working environment around the kiln. However, in the preheating and firing zone in the kiln, the green body and combustion gas produce a large amount of water vapor, which will inevitably enter the inner surface of the kiln shell through the tiny pores of the kiln insulation wall. At this time, the shell temperature is lower than 100°C, and condensation may occur on its inner surface, and the shell is corroded by condensation water. In other words, the kiln shell should be kept at a low temperature to improve the working environment, so the inner surface of the shell is susceptible to condensation. On the contrary, in order to prevent condensation, the shell temperature needs to be increased, and the working environment will deteriorate. Therefore, in response to this conflicting problem, a certain manufacturer provides a tunnel kiln wall design scheme.

The design scheme is to form an air circulation space between the kiln wall and the shell, and the upper and lower parts form air intake and exhaust ports that are connected to the outside of the kiln wall and can be switched. Refractory inclusions forming connecting holes can also be set in the circulation space to connect the air intake and exhaust ports. The inclusions can also be formed into a cubic shape using refractory sheets.

Design Example 1

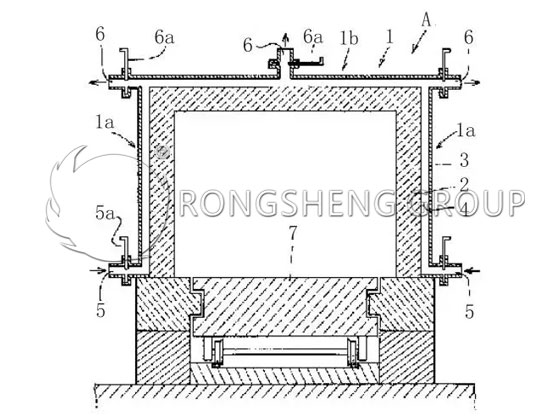

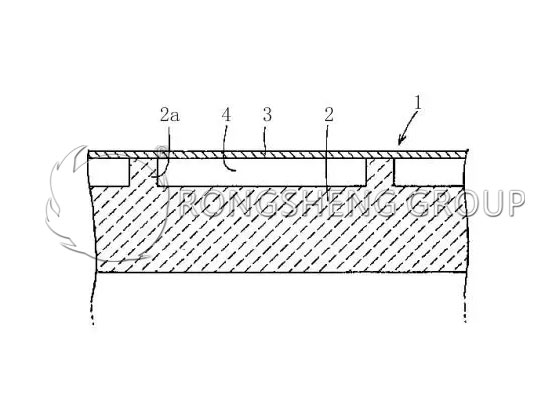

As shown in Figures 1 and 2, the tunnel kiln consists of side walls and a kiln roof that is horizontally mounted above the two side walls. The blanks loaded on the kiln car are fired as the car moves in the kiln space. The kiln wall consists of a thicker refractory wall composed of refractory bricks and ceramic fibers and a steel shell covering the outside of the refractory kiln wall. A space is set between the refractory kiln wall and the kiln shell. Multiple extensions are formed on the outside of the refractory wall, and their top surfaces are fixed to the inner surface of the kiln shell, so that the refractory wall is supported on the shell. Most of the range except the extension between the refractory wall and the kiln shell forms a circulation space for air circulation. An opening is opened at the lower end of the space to connect the circulation space with the outside of the kiln. At the same time, an opening is opened at the upper end of the side wall and the center of the kiln roof to form an exhaust port to connect the circulation space with the outside of the kiln. Each air intake and exhaust port is equipped with an air brake to control the opening and closing of each port and the opening degree of the regulating valve.

A-tunnel kiln; 1-kiln wall; 1a-side wall; 1b-kiln roof; 2-refractory wall; 3-kiln shell; 4-circulation space; 5-air intake; 5a-airlock; 6-exhaust port; 6-airlock

1-kiln wall; 2-refractory wall; 2a-extending part; 3-kiln shell; 4 circulation space

With such a system design, the internal space of the kiln wall is at a high temperature. Due to the double insulation effect of the refractory wall and the air layer in the circulation space, the kiln shell is maintained at a lower temperature, and the ambient temperature around the kiln is also lower, which brings a good working environment. During the preheating and firing process, a large amount of water vapor generated by the green body and combustion gas passes through the tiny gap inside the refractory wall, moves from the inner surface of the refractory wall to the outer end, and flows into the circulation space. It rises together with the low-humidity external air introduced by the open air intake port and is discharged out of the kiln through the open exhaust port. By adjusting the opening of the air dampers at the air intake and exhaust ports, the amount of outside air flowing into the space can be controlled, so that the circulation space is always kept at a low temperature. The kiln shell is prevented from contacting high-humidity air, and the shell temperature is below 100°C, so that condensation will not occur. It can be seen that this can not only keep the kiln shell at a low temperature and improve the operating environment around the kiln, but also prevent condensation and avoid erosion of the kiln shell, achieving two goals at one stroke. In addition, refractory bricks are used on the kiln wall to ensure its high strength. The exhaust port can also be connected to a fan to recover the hot air in the circulation space and use it as a heat source for the blank drying process.

Design Example 2

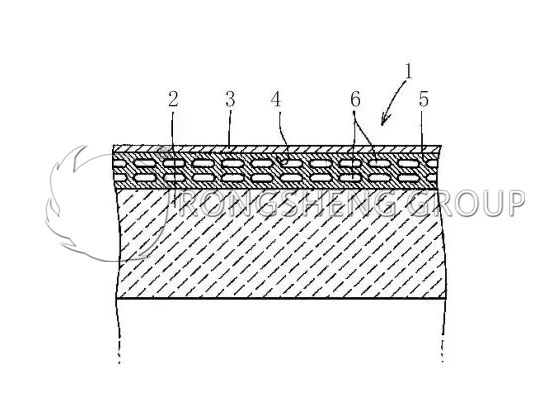

As shown in Figure 3, the circulation space set between the refractory wall and the kiln shell is filled with refractory sandwich materials, which are closely attached to the outside of the refractory wall and the inner surface of the kiln shell. Many connecting holes are formed in the inner part of the sandwich materials from the lower end to the upper end surface, which are connected with the air intake and exhaust ports of the circulation space. The thick sandwich materials can ensure high strength, so that the refractory wall is supported on the kiln shell. Due to the low thermal conductivity of the refractory wall and the low thermal conductivity of the sandwich materials, the heat insulation effect of the sandwich materials to prevent heat from radiating from the refractory wall to the inner surface of the kiln shell can ensure that the kiln can be kept at a low temperature. The water vapor generated in the inner space of the kiln wall enters the connecting holes through the gaps in the refractory wall and the inner part of the sandwich materials, and will not contact the inner surface of the kiln shell, but will go up with the external air introduced by the air intake port and be discharged from the kiln through the exhaust port. This not only keeps the kiln shell at a low temperature, but also prevents condensation caused by the inner surface of the kiln shell contacting with water vapor.

1-kiln wall; 2-refractory wall; 3-kiln shell; 4-circulation space; 5-core material; 6-connecting hole

Design Example 3

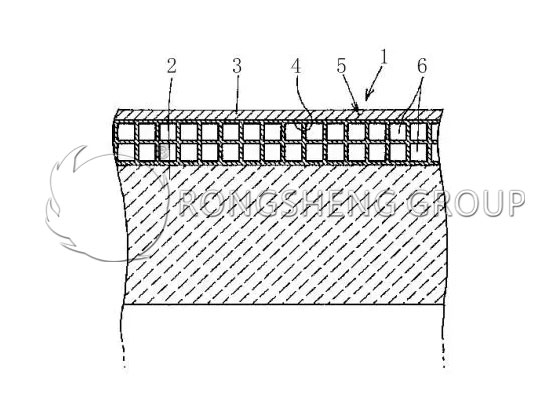

The inner surface of the kiln shell is fixed to the base end of the columnar bolt, extending across the circulation space and connected to the outside of the refractory wall. The circulation space is also filled with a sandwich material. The sandwich material is formed with many three-dimensional connecting holes with a square cross-section in the vertical direction of the ceramic fiber sheet (as shown in Figure 4). Since the sandwich material is thin at each part, it is easy for the bolts to penetrate. The bolts inserted into the circulation space support the refractory wall. In terms of this kiln wall structure, the sandwich material is filled in the circulation space, which also prevents the heat radiation to the kiln shell, keeps it at a low temperature, and also prevents the kiln shell from contacting water vapor and causing condensation.

In summary, the above kiln wall structure design is adopted, and the refractory wall and the air layer in the circulation space have a double insulation effect, the kiln shell is kept at a low temperature, and the operating environment around the kiln is effectively improved. The air in the circulation space is kept at a low and moderate state, the inner surface of the kiln shell is not in contact with high humidity air, the kiln shell temperature is below 100°C, and no condensation is generated on its inner surface, eliminating the erosion of the kiln shell by condensation.

How to Choose a Kiln that Suits You?

The structure and advantages, and disadvantages of shuttle kilns, tunnel kilns, and roller kilns. Enterprises can choose kilns that suit them according to their product structure, output, and economic capabilities. The following are some suggestions from Rongsheng Refractory Material Factory based on years of sales and construction experience.

- For daily output below 20m3, and there are many types of products, the firing temperature is different. Since its own output is difficult to meet the production volume of the tunnel kiln, it is recommended to use a fast-firing shuttle kiln.

- For daily output or more than 20m3, but its glaze color is complex, such as kiln-changed crystallized glaze, requires a certain constant temperature and cooling time. From the economic considerations of your kiln construction, you can use a traditional shuttle kiln or an electric shuttle kiln. If the kiln-changed glaze or crystallized glaze is only part of it, you can choose a fast kiln. The fast kiln is not only fast, but also slow. Slow, the temperature difference can be controlled very small, but the slow energy-saving effect is poor.

- For artistic ceramics, daily-use ceramics, and sanitary ceramics with a temperature of less than 1300°C and a large output, it is recommended that you use a roller kiln or a large fast shuttle kiln.

- For high-output, high-height, heavy-weight, high-temperature, and single-glaze ceramics, a trolley-type tunnel kiln can be used. Such as high-temperature daily-use ceramics and sanitary ceramics.

To purchase high-quality refractory lining materials for kilns, please choose Rongsheng. Contact Rongsheng for free samples and quotes.