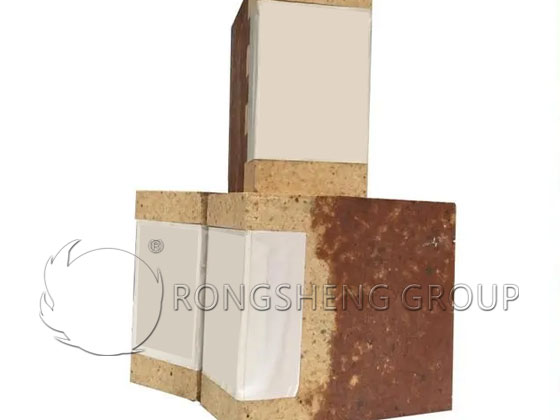

Corundum mullite castable mainly uses dense corundum and mullite as aggregate. Then white corundum powder, Al2O3 powder and mullite powder are used as fine powder to make corundum mullite refractory castable.

Corundum mullite refractory castable has the common characteristics of corundum castable and mullite castable. For example, high strength at high temperature, good thermal shock resistance and structural spalling resistance. It also has the advantages of good thermal shock resistance, high softening temperature under load, low creep rate at high temperature and good chemical corrosion resistance. It is widely used in large power plant boiler anti-wear lining and other high temperature furnace lining.

This series of refractory castables are recommended to be used in front and back of large cement kilns, coal injection pipes and other industrial kiln lining. Corundum mullite refractory castable belongs to the middle and high – grade refractory. It uses the material performance is outstanding, the purity is high, the performance in all aspects is superior to the clay, the high aluminum refractory castable.

First of all, the temperature of steel and mullite castable is very high, and the temperature of ordinary refractory castable is around 800℃900℃. The normal high aluminum castable has a service temperature of about 1300℃, while the corundum mullite castable has a service temperature of up to 1500℃, which is close to the service temperature of corundum castable. Secondly, the thermal shock resistance stability is very good. Finally, the refractory castable has high temperature material erosion resistance, has a good thermal shock resistance, the use of very cold and very hot parts, especially suitable for the kiln has high temperature high-speed running material parts.

I believe that after reading the above article, you have a certain understanding of corundum mullite castable. If you have any questions about refractories, please feel free to contact us by email and we will answer them in detail.