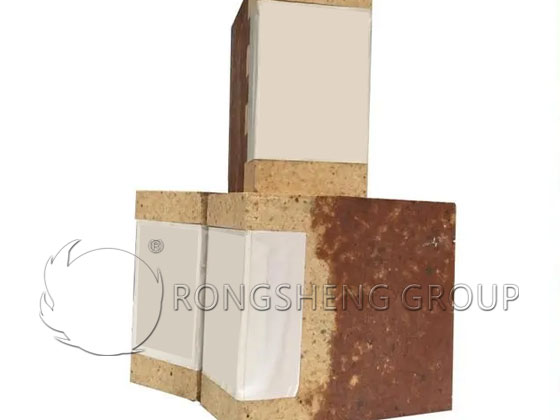

Improved calcium silicate slab, its main components are calcium hydroxide and quartz sand, and reinforced fibers are added to improve its performance. It is also called reinforced calcium silicate slab. This board is favored for its good strength and construction convenience. At the same time, it has low thermal conductivity, making it an ideal choice for thermal insulation projects such as boilers, kilns, heating furnaces, and kiln walls. Contact Rongsheng for free samples and quotes.

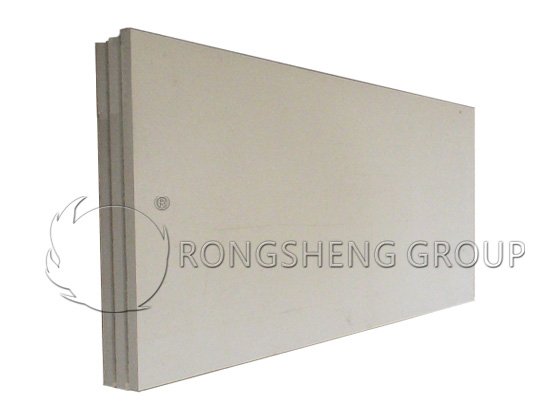

Reinforced Calcium Silicate Slab

Performance parameters of enhanced calcium silicate board

- Density: not less than 230kg/m³

- Flexural strength: not less than 0.4 MPa

- Compressive strength: not less than 0.8 MPa

- Linear shrinkage: not more than 2%

- Thermal conductivity: not more than 0.069

- Using temperature: up to 1050℃

Fiber-reinforced calcium silicate board: Advantages of a new type of lightweight board

Fiber-reinforced calcium silicate board is a new type of lightweight board. The main raw materials include cementitious materials such as calcium materials and silicon materials and reinforcing fibers (such as cellulose fibers, alkali-resistant glass fibers, etc., replacing traditional asbestos fibers). It is made by molding and steam or high-pressure steam curing.

Specifications: The size of the fiber-reinforced calcium silicate board is 12202440mm, and the thickness is between 6-20mm.

Performance of fiber-reinforced calcium silicate board

- Lightweight: lightweight, easy to carry and install.

- High strength: has high strength and is not easy to deform.

- Fireproof: good fire resistance and not easy to burn.

- Smokeless: no smoke when burning, safe and environmentally friendly.

- Waterproof: has good waterproof performance and is suitable for humid environments.

- Moldproof: mildew-proof and moisture-proof, keep dry.

- Soundproof: good sound insulation, suitable for places that require a quiet environment.

- Heat insulation: excellent heat insulation performance, keeping the indoor temperature stable.

- No deformation: not easy to deform, keep flat.

- No cracking: good durability, not easy to crack.

Application advantages of fiber-reinforced calcium silicate board

Through process improvement, the improved calcium silicate board shows higher strength, which makes it less likely to break during construction, effectively reducing construction losses and costs. In addition, its bending resistance has also been improved, and it can maintain its shape even in long-term high-temperature environments, ensuring the stability of the refractory structure and extending its service life.

Application scope of fiber-reinforced calcium silicate board:

The application scope of this board is very wide, covering multiple industries such as metallurgy, petrochemicals, cement, ceramics, glass, electricity, shipbuilding and non-ferrous metals. Its main application scenarios include heating furnaces, soaking furnaces, high-temperature flues and pipelines, decomposition furnaces, preheaters, tertiary air ducts, smoke chambers, tunnel kiln walls, melting furnaces and other high-temperature equipment and structures.

Differences between Calcium Silicate Board and Fiber-Reinforced Calcium Silicate Board

Calcium silicate board is a board with loose short fibers such as inorganic mineral fibers or cellulose fibers as reinforcing materials and siliceous-calcium materials as the main bonding materials. Its production process includes pulping, molding, and then curing reaction in high-temperature and high-pressure saturated steam to finally form calcium silicate gel.

Fiber-reinforced calcium silicate board is a decoration material manufactured by a special process. It uses silicon and calcium as the main components and uses exquisite technologies such as rolling and pressing. After pressure steam curing and surface polishing, a calcium silicate board with a mullite (C5S6H5) crystal structure is generated, which significantly enhances the performance of the material.

In a high-temperature and high-pressure environment, the calcium material and the siliceous material in the base material of the fiber-reinforced calcium silicate board are autoclaved and cured to undergo a hydrothermal synthesis reaction, thereby forming tobermorite with a stable crystal structure. This stable material makes the board have a very small shrinkage rate when affected by temperature and humidity. Compared with ordinary calcium silicate boards, the fiber-reinforced calcium silicate board uses more than 5% reinforcing fiber, which makes it not only low in density, moisture-proof, moth-proof, and mildew-proof but also has excellent processability. Such as nailing, sawing, planning, drilling, bonding, etc. In addition, fiber-reinforced calcium silicate board shows excellent performance in strength, shrinkage, swelling, and flexural deformation.

Fiber-reinforced calcium silicate board not only has excellent fire resistance, but also remains stable in an open flame environment, without cracking or burning, and does not produce smoke or toxic gases, ensuring safe use. In addition, it is also a new type of building and industrial board with excellent performance, which has multiple functions such as fire prevention, moisture resistance, sound insulation, and moth resistance, and has excellent durability, making it very suitable as a decorative material for suspended ceilings and partitions.