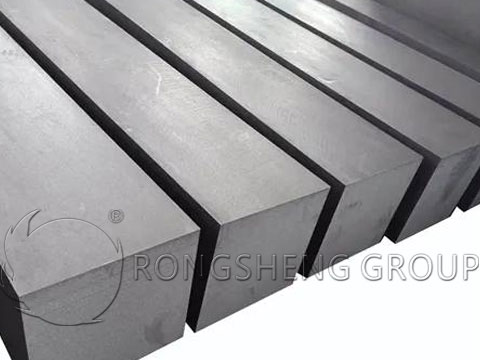

A graphite block, as the name suggests, is a block of graphite. There are two shapes of graphite blocks for sale: round and square. Engaged in the graphite industry for ten years, the graphite blocks produced have reached hundreds of tons. Graphite blocks are very versatile because graphite has many excellent properties. For example, it has high-temperature resistance, a melting point of 3800 degrees, a boiling point of 4000 degrees, good electrical conductivity, corrosion resistance, acid, and alkali resistance, and is a relatively stable substance in nature. Therefore, graphite is an excellent material.

Applications of High-Purity Graphite Blocks

High-purity graphite block refers to block-shaped high-purity graphite. High-purity graphite comes in two forms: bulk and powder. Powdered high-purity graphite is called high-purity graphite powder, and block-shaped high-purity graphite is called high-purity graphite block. It is all made of high-purity graphite as raw material and can be made of high-purity graphite blocks into high-purity graphite products of various shapes, specifications, and different uses.

Due to the many excellent properties of graphite, high-purity graphite blocks are widely used. Application fields of high-purity graphite blocks. High-purity graphite blocks are primarily used in industrial electrical conductivity and metallurgy.

The Use of Graphite Blocks

Graphite blocks cut from graphite are also very versatile. Graphite blocks are mainly used for silicon carbide furnaces, graphitization furnaces and other metallurgical furnaces, resistance furnaces as furnace linings and conductive materials, and impermeable graphite heat exchangers. Widely used in electronics, metallurgy, chemical industry, steel, and other fields, the product quality is good and the performance is stable.

Graphite has the advantages of small resistivity, high-temperature resistance, corrosion resistance, good thermal shock resistance, small thermal conductivity, small expansion coefficient, self-lubricating, and easy precision machining. Therefore, graphite blocks are ideal for inorganic non-metallic crucibles and heaters for single crystal furnaces. EDM graphite, sintering molds, electron tube anodes, metal coating, graphite crucibles for semiconductor technology, graphite anodes and grids for electron emission tubes, thyratrons, mercury arc rectifiers, etc.

Graphite blocks can also be used in graphite equipment

What is the role of graphite blocks in graphite equipment? The graphite blocks used for making graphite heat exchangers and graphite absorber equipment are called graphite heat exchange blocks and graphite absorption blocks. Generally speaking, the pores of the purchased graphite block contain a small amount of water, which needs to be dried first to evaporate water. This process is carried out in an electric oven, the temperature is controlled within 350°C, and the drying time is about 1-2 hours. During drying, water vapor is mainly produced, and no other waste gas is produced. In the manufacture of graphite heat exchanger and graphite absorber equipment, because the heat exchange block absorber block is only subjected to pressure and is an integral structure, there is no glue joint. Therefore, it has high structural strength and good impact resistance and plays an important and irreplaceable role in graphite equipment.

The performance of graphite block in the electrolysis industry

Graphite blocks are used as conductive electrodes in industries such as the electrolysis of magnesium metal. Graphite blocks are also widely used in the production of corrosion-resistant heat exchange equipment and furnace building materials for high-temperature furnaces in the chemical industry.

The production of graphite blocks varies according to the requirements of the user, some need to be impregnated with coal pitch before graphitization, and some do not. The graphite block used as a conductive electrode in the electrolysis industry can be properly extended in service life by impregnating it with coal tar. Before leaving the factory, the graphite block is checked for its specific resistance and compressive strength. The graphite block used as the conductive electrode of the electrolysis device has high-quality requirements. As a graphite block for making heat exchange equipment and building high-temperature furnaces, it can also be used with a higher specific resistance.

Dimensional Deviation of Graphite Block

The shape of the graphite block should meet the following requirements.

- The edges and corners are dropped. The depth is not more than 20mm (not more than 10mm), the length is not more than 80mm, and each piece is not more than two places.

- Cracks. For graphite blocks of 220×220mm and 400×115mm, the surface crack width is less than 0.3mm, the width is 0.3~1.0mm, the length is not more than 100mm, and each block is not more than two places. 400×400mm graphite block, the crack width is less than 0.5mm, the length is less than 50mm, the width is 0.5~1.0mm, and the length is 50~100mm, there are no more than two places per block.

Rongsheng Graphite Blocks Suppliers provide high-quality graphite block products, if you need to buy even products, for example, graphite electrodes, graphite blocks, graphite powder, graphite bricks, etc. Please contact us and we will provide you with the most suitable product according to your specific usage needs.