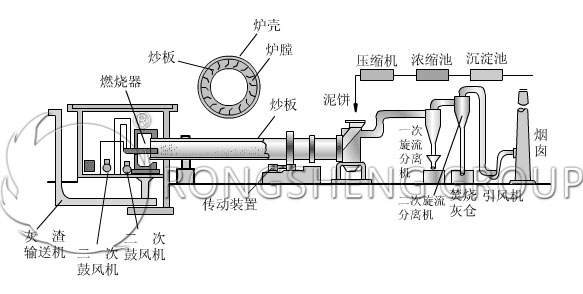

The core equipment for incinerating organic waste liquids is the incinerator. Different furnace types are selected based on the properties of the waste liquid and treatment requirements. Currently, the incineration of organic waste liquids is becoming increasingly popular, and the refractory materials used in incinerators are a key constraint to this method. Regardless of the material used for the refractory lining, during industrial production, it is subject to long-term high temperatures, high pressures, temperature fluctuations, atmosphere changes, and erosion from slag. Refractory damage typically occurs through erosion, scouring, and cracking. Erosion is continuous damage, while cracking and spalling are discontinuous damage. After erosion, the refractory material will form cracks due to a mismatch in the internal thermal expansion coefficient. The damage mechanism of the refractory lining is related to factors such as the lining’s mineral composition, its microstructure, its chemical composition, and the type of slag.

Damage to Refractory Materials Used in the Lining of Organic Waste Liquid Incinerators

Damage mechanism of refractory materials used in organic waste liquid incinerators. The causes of damage can be summarized into the following four categories:

- (1) Mechanical erosion and wear. Mechanical wear is caused by the friction between two relatively moving objects on the contact surface. It can convert the mechanical energy of the object itself into heat energy, resulting in wear of the refractory material. During the movement in the furnace, the material will have a large mechanical erosion and wear on the lining of the furnace, causing deformation, wear, and even cracking of the lining refractory material, causing serious damage to the lining of the incinerator.

- (2) High-temperature dissolution of refractory materials. In refractory materials, non-main components brought in by raw materials and production processes are called impurities. At high temperatures, impurities easily react chemically with the main components in the raw materials to form a low-melting-point phase. This process is called high-temperature dissolution of refractory materials.

- (3) High-temperature solution penetration. High-temperature solution penetration is also called slag erosion. At high temperatures, slag exists in a molten phase. After the liquid slag corrodes the refractory material, it will form a low-melting-point phase with its oxide. Therefore, the essence of slag corrosion is liquid slag corrosion. That is, it is mainly the dissolution of the refractory material in the slag and the penetration of the slag into the interior of the refractory material.

- (4) Gas phase volatilization at high temperatures. The gas phase volatilization of refractory materials mainly refers to the loss caused by oxidation reactions. Evaporation reactions mainly occur in oxidizing refractory materials, while oxidation reactions mainly occur in non-oxidizing refractory materials, non-oxide refractory materials, and oxide composite refractory materials. Among them, more than half of the damage to refractory materials during service is caused by slag corrosion.

One of the key issues in the incineration of organic wastewater is refractory corrosion. During the incineration process, alkali metal salts in the organic wastewater easily form low-melting-point eutectic salts, leading to coking and slagging in the incinerator at high temperatures. After long-term operation, the refractory lining is severely corroded by the incineration residue, which can cause significant economic losses and safety accidents. Improving the corrosion resistance of refractory materials and extending their service life has practical economic benefits.

Related research has examined the thermal corrosion of Al2O3−SiO2 refractory materials by sodium and sulfur vapor in hazardous waste incinerators at temperatures between 930 and 1000°C. This research demonstrates that the reaction between Na2SO4 and SiO2 first leads to the formation of liquid sodium silicate (Na2Si2O5) and slow corrosion creep. This is followed by corrosion from nepheline (NaAlSiO4) and albite (Na8Al6Si6O28S), leading to lining cracking. Because zirconium- and chromium-containing bricks have high heat resistance, attempts have been made to improve the corrosion resistance of incinerator refractories to organic wastewater by using these materials. The addition of ZrO2 improves the thermal stability and corrosion resistance of Al2O3-Cr2O3 refractory linings in high-temperature incinerators. Researchers used a static corrosion method to evaluate the thermal corrosion of Al-Cr-Zr bricks using incinerator slags with varying potassium and sodium contents. The study demonstrated that Al-Cr-Zr bricks are resistant to corrosion by potassium and sodium salts. However, when the salt content exceeds 4%, the compressive strength of Al-Cr-Zr bricks decreases sharply.

Repair of Incinerator Refractory Materials

The repair method for incinerator refractory materials should be selected based on the extent of damage and location. The following are some common methods and key points:

Refractory Concrete Repair

Material Preparation: Use high-alumina cement (grade no less than 425), expanded clay or brick sand, expanded vermiculite, etc., ensuring that the materials meet relevant standards.

Pre-construction Preparation: Remove the damaged lining from the damaged area and clean the construction tools. Soak the expanded clay for at least 12 hours and drain thoroughly.

Construction Method:

- Applying Method: Suitable for small-area repairs. Fill the wire mesh with concrete and smooth it with a wooden trowel. Keep the surface rough and avoid calendering to prevent cracks.

- Spraying Method: Suitable for large-area repairs with thicker thicknesses (greater than 50mm). Use a semi-dry spraying method, controlling the water-cement ratio and spray pressure to ensure a uniform and dense coating.

- Formwork Casting: Suitable for large-area, thick vertical lining repairs. Pour in layers and tamp manually to avoid stratification of lightweight aggregate and cement caused by mechanical tamping.

Refractory Fiber Adhesive Repair

Applicable Scenario: Suitable for lining surfaces experiencing delamination, powdering, or chipping.

Instructions: First, scrape off the powdered layer and level it. Hand-apply the original material to any large cracks or chipping areas. Then, apply the refractory fiber felt. Before applying, clean the surface to ensure there are no loose materials. Start at the base of the wall and work upwards, applying the adhesive thoroughly and compacting firmly.

Repair of Specific Areas

Front and rear arch areas: This area is susceptible to corrosion from high-temperature flue gas and fly ash. Corundum-silicon carbide or silicon carbide materials containing silicon carbide can be used to improve ash corrosion resistance and adhesion.

Air-cooled furnace walls: If bulging occurs, increase the number of anchor bricks, especially at the slope and grate section connections. This also improves the strength and installation quality of the anchor bricks and optimizes the furnace wall construction process.

Precautions

- Maintain the construction environment temperature between 10-25°C and at least 5°C during curing to prevent the lining from freezing.

- Strictly control the water-cement ratio and construction time, and use the mixed mixture within 30 minutes.

- After repair, perform curing and inspection. If voids or interlayers are found, promptly repair them.

The above methods should be selected based on the actual damage. It is recommended that a professional construction team perform the repair to ensure effective and safe repairs.