Magnesia chrome brick is mainly used in metallurgy industry, such as building open hearth furnace roof, electric furnace roof, furnace refining furnace and a variety of non-ferrous metal smelting furnace. The high temperature part of the wall of the ultra- high power electric furnace adopts fused cast magnesia chrome brick, the high-erosion area of the refining furnace outside the furnace adopts magnesia chrome brick made of synthetic material, and the high-erosion area of the non-ferrous metal flash melting furnace adopts fused cast magnesia chrome brick and the magnesia chrome brick made of synthetic material. In addition, magnesia chrome refractory brick is also used in cement rotary kiln firing belt and glass kiln regenerator and other parts.

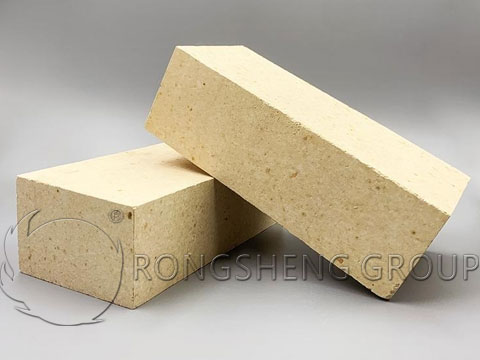

Magnesia chrome brick is an alkaline firebrick whose main crystal phases are square magnesite and magnesia aluminum spinel. Magnesia chrome refractory brick features remarkable features, high refractory temperature, high softening edge shape temperature under 0.2mpa load, strong resistance to alkali slag, high high temperature strength, high temperature volume stability, also has standard size accuracy, easy to construct, can be customized to the drawing processing size.

This series of refractory brick is usually used to produce mgo-cr2o3 series products from magnesia, chromium ore, synthetic magnesia and chromium sand, sometimes with a small amount of additives. Sintered magnesia and electrofused magnesia with different MgO contents (generally greater than 89%) are combined with refractory chromite, chromium concentrate, sintered or electrofused magnesia chrome sand with different Cr2O3 contents (sometimes a small amount of chromium green is added) to produce a variety of magnesia chrome products. Nowadays the commercial intercourse popular more variety formulation has the magnesia chromium brick, the direct union, the recombination (the half recombination), does not burn the magnesia chrome brick and so on.

Ordinary magnesia chrome brick is generally produced from sintered magnesia (MgO content between 89% and 92%) and refractory chrome brick. Due to many impurities, the refractory grains are combined with silicate. The content of Cr2O3 in chromium ore used in the production of magnesia chrome refractory brick is generally above 33%. Chromite generally consists of two components: chromite grains and gangue minerals. Chromite particle is spinel solid solution, the gangue in chromite is magnesium silicate; Serpentine, leaf serpentine, peridotite, talc, chlorite and other gangue stones are usually filled in the cracks of chromium ore particles. When gangue containing crystal water, such as serpentine, talc, has a thick interlayer, the gangue material is added to make bricks. When fired at high temperature, the crystal water is released and holes are formed on the surface of the bricks.

With the continuous improvement of material and production process of magnesia chrome brick, the variety of magnesia chrome brick is also increasingly enriched. For example: silicate bonded magnesia chrome brick, directly bonded magnesia chrome brick, fused cast magnesia chrome brick, capacitor bonded magnesia chrome brick, semi-bonded magnesia chrome brick and fully synthetic magnesia chrome brick and so on.

We are a professional refractory material manufacturer, for many years, has been committed to the production of high quality refractory products, products export quality is stable and reliable, reasonable price, rapid delivery, after-sales protection, won the customer’s praise and trust. Welcome to consult purchasing.