In the world of construction and industrial applications, selecting the right materials is crucial for ensuring durability, safety, and overall project success. One such essential material is High Alumina Cement (HAC), a key component in many high-temperature and refractory applications. Whether you’re involved in the construction of furnaces, kilns, or other structures exposed to extreme heat, understanding the benefits and sourcing the best high alumina cement can make a significant difference.

What is High Alumina Cement?

High Alumina Cement is a type of hydraulic binder with a significant proportion of alumina (Al2O3) content, typically ranging from 50% to 80%. This high alumina content imparts several unique properties to the cement, making it ideal for specialized applications. Unlike ordinary Portland cement, which primarily contains calcium silicates, HAC develops strength rapidly and performs exceptionally well in high-temperature environments.

Key Properties of High Alumina Cement

High alumina cement is known for several distinct properties that make it stand out:

- High Thermal Resistance: Due to its high alumina content, HAC is highly resistant to extreme temperatures. It can withstand heat up to 1,500°C (2,732°F), making it suitable for refractory applications such as lining furnaces, boilers, and incinerators.

- Rapid Strength Gain: One of the most notable features of HAC is its rapid strength development. It can achieve high compressive strength within 24 hours, which is particularly advantageous for projects with tight timelines.

- Corrosion Resistance: HAC exhibits excellent resistance to chemical attacks, especially in acidic and sulfate-rich environments. This makes it a preferred choice for structures exposed to aggressive conditions, such as sewage treatment plants and chemical processing facilities.

- Low Porosity: The dense microstructure of HAC reduces its porosity, enhancing its durability and resistance to water penetration. This property is essential for applications where water resistance is critical.

- Versatility: HAC is compatible with various aggregates and can be used in a wide range of formulations, making it versatile for different construction and industrial uses.

Applications of High Alumina Cement

High alumina cement’s unique properties make it suitable for a variety of specialized applications:

- Refractory Castables: HAC is a key ingredient in refractory castables, which are used to line high-temperature furnaces, kilns, and incinerators. Its ability to withstand extreme heat and resist thermal shock ensures the longevity of these structures.

- Industrial Flooring: In environments where floors are exposed to high temperatures, chemicals, or heavy mechanical loads, HAC-based concrete provides a durable and long-lasting solution.

- Sewage Treatment Plants: The corrosion resistance of HAC makes it ideal for use in sewage treatment facilities, where the cement must withstand acidic and sulfate-rich conditions.

- Rapid Repair Works: Due to its quick-setting nature, HAC is often used in emergency repair works, such as fixing roadways, bridges, and other critical infrastructure.

- Chemical Processing Plants: HAC’s resistance to chemical attacks makes it suitable for constructing tanks, vessels, and other structures in chemical processing plants.

Why Quality Matters in High Alumina Cement

When it comes to sourcing high alumina cement, quality should be a top priority. The performance of HAC in critical applications depends heavily on its chemical composition, particle size distribution, and manufacturing process. Poor-quality HAC can lead to premature failure, reduced strength, and compromised safety.

Key Factors to Consider:

- Alumina Content: The alumina content in HAC is a primary indicator of its quality. Higher alumina content generally translates to better performance in high-temperature and corrosive environments. Ensure that the HAC you purchase meets the required alumina percentage for your specific application.

- Setting Time: The setting time of HAC can vary depending on its formulation. It’s important to choose a product with a setting time that aligns with your project requirements. For rapid repairs, opt for a quick-setting variant, while for large-scale applications, a slower-setting HAC may be more suitable.

- Compressive Strength: The compressive strength of HAC is a critical factor in determining its load-bearing capacity. Always verify that the HAC meets the specified strength requirements for your project to ensure structural integrity.

- Manufacturer Reputation: The quality of HAC can vary significantly between manufacturers. Choose a supplier with a strong reputation for producing consistent, high-quality products. Look for certifications, customer reviews, and industry recognition as indicators of reliability.

Where to Buy High Alumina Cement

Given the specialized nature of high alumina cement, it’s important to source it from reputable suppliers. Here are some tips for finding the right supplier:

- Research and Compare: Start by researching different suppliers and comparing their products, prices, and customer reviews. Look for suppliers that have a track record of delivering high-quality HAC.

- Check for Certifications: Reputable suppliers will have certifications that attest to the quality of their products. These certifications ensure that the HAC meets industry standards for chemical composition, strength, and performance.

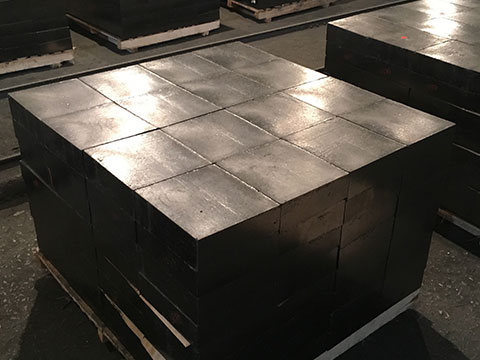

- Consider Bulk Purchasing: If you’re involved in a large-scale project, consider buying HAC in bulk. Many suppliers offer discounts for bulk purchases, which can help you save money while ensuring you have a consistent supply of cement.

- Ask for Samples: Before making a large purchase, ask the supplier for samples of their HAC. Testing these samples in your specific application can help you determine if the product meets your quality and performance expectations.

- Customer Support: A reliable supplier will offer excellent customer support, helping you choose the right product for your needs and providing assistance throughout the purchasing process.

Rongsheng High Alumina Cement for High-Temperature and Industrial Applications

High Alumina Cement is an essential material for many high-temperature and industrial applications. Its unique properties, including high thermal resistance, rapid strength gain, and chemical resistance, make it a preferred choice for demanding environments. When sourcing high alumina cement, quality should be your top priority. By understanding the key factors that influence HAC quality and choosing a reputable supplier, you can ensure that your projects benefit from the best possible materials. Whether you’re constructing a refractory lining, repairing infrastructure, or building in a corrosive environment, high alumina cement offers the durability and performance you need for success.