The monolithic refractory material is an inorganic non-metallic material with a refractoriness of 1580℃, which is mainly used in metallurgy, chemical industry, and electric power industry. As a branch of unshaped refractory materials, refractory castables are developing relatively quickly, and their use effects are also very attractive. But it is easy to misunderstand: There is only one type of refractory castable? the answer is negative. Refractory castables have developed to the present, and the composition of their raw materials is various, and their construction methods are also varied. Therefore, the statement that there is only one type of refractory castable is wrong. Among them, high alumina castables are a relatively common type of unshaped refractory for kiln lining.

The Relationship Between the Ratio of High-Alumina Castables and Physical and Chemical Indicators

When refractory castables are prepared, they are mainly determined according to the percentage of raw materials. The performance of high alumina castables as refractory material used in circulating fluidized bed boiler return device is also very commendable. In many European countries, the refractory castable is also refractory concrete. Therefore, high alumina refractory castables can also be called high alumina refractory concrete. So what is the direct relationship between the ratio of high-alumina castables and physical and chemical indexes?

When preparing high-alumina castables, high-alumina bauxite aggregates are mainly used, which accounts for about 65 to 70%. High alumina cement is 7-10%. Five to eight percent of silica fume and alumina powder. The fine bauxite powder is 15% to 24%, and the water reducing agent is 0.2%. According to the time of construction, choose a suitable admixture or coagulant to prepare an unshaped refractory. When high alumina castables are used, after the high-alumina castables are formed and initially set, the standard curing time is 28 days, and the compressive strength can reach 40-60MPa. Its characteristics are slow hydration speed, high later strength, and high refractoriness.

The alumina content of high alumina castables is generally about 70%, and 2% stainless steel fibers can be added during construction according to the conditions of use. In order to increase the wear resistance of the castable and enhance the service life of the high-alumina castable. To talk about the relationship between the ratio of high-alumina castables and physical and chemical indicators, many factors need to be considered. Because many people think that the ratio of high alumina castables and physical and chemical indicators are determined by the physical and chemical indicators, and some people think that the physical and chemical indicators are determined by the ratio. And there is no accurate answer to this question. Because many manufacturers now support customized castables, just like Rongsheng refractory manufacturers, generally sold castables are prepared according to the needs of customers and the parts used. Its performance also fully meets the requirements of the kiln lining. However, it should be noted that whether it is customized or general high-alumina refractory castables, it is necessary to comply with the physical and chemical indicators of the castable when purchasing, otherwise many unexpected phenomena are likely to occur.

In short, no matter what type of refractory castable is prepared, the prepared castable must meet the physical and chemical indicators of the standard.

The Performance Index of High Alumina Castable

| Items | RS-01 | RS-02 | |

| Al2O3 % | 75 | 80 | |

| Refractoriness ℃ | 1480 | 1680 | |

| Linear Change Rate after Burning % | -0.01 | -0.3 | |

| Crushing Strength MPa ≥ | 110℃ × 24h | 20 | 30 |

| 1100℃ × 4h | 60 | 70 | |

| Flexural Strength MPa ≥ | 110℃ × 24h | 9 | 11 |

| 1100℃ × 4h | 10 | 12 | |

| Maximum Use Temperature ℃ | 1480 | 1680 | |

Advantages of High Alumina Castables

High-alumina castable is one of the hot-selling refractory castables of refractory manufacturers. Many refractory manufacturers’ partners for many years are their loyal buyers. 90% of customers who use high-alumina castables will repurchase them, so what is the charm of it?

High-alumina castable is a kind of low-cement castable, with a cement content of less than 8%. It is a refractory castable made by mixing high alumina bauxite clinker as aggregate, refractory clay as powder, adding aluminate cement, and sodium tripolyphosphate according to the formula ratio. Its service temperature is above 1400 degrees and its alumina content reaches 74%. It is a commonly used castable for kiln lining. High alumina castables have the characteristics of high refractoriness, strong thermal stability, and good thermal shock resistance. Different from ordinary refractory castables, most of the calcium aluminate cement in the matrix is replaced by ultrafine powder. At the same time, it is a product that meets and exceeds the performance of ordinary cement castables by adding appropriate additives.

Characteristics of High Alumina Castable

- High mechanical strength.

- Good wear resistance and corrosion resistance.

- Good thermal shock resistance.

Use of High Alumina Refractory Castable

Suitable for all kinds of heat treatment furnace linings and burners, blast furnace hot blast furnaces, heating furnaces, electric furnace tapping troughs, shaft kiln high-temperature sections, rotary kiln heads, power plant boilers, and other industrial furnace linings.

Rongsheng Unshaped Refractory Castable Manufacturer

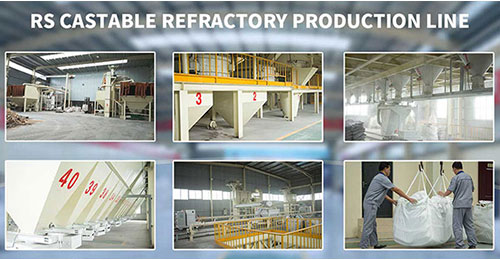

Rongsheng is a manufacturer and sales company with an advanced and fully automatic production line of unshaped refractory materials. Rongsheng’s unshaped refractory production line has an annual output of 80,000 tons. It played an inestimable role in the turnkey project of the chemical furnace. In addition, with the support of our technical team, our customers have also found the wear-resistant refractory castables, refractory plastics, refractory ramming materials, and other products they need to produce. If you need to buy monolithic refractories, high alumina refractory castables, please contact us. We will provide you with services according to your specific needs.