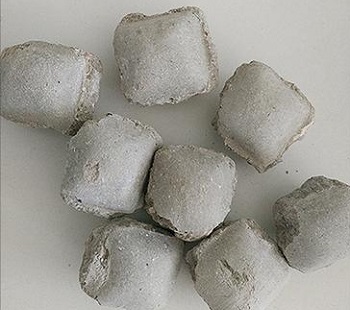

Light burned magnesia pellets is a folding, pressure – resistant, high – strength, air – hard cementing material. I plant production and manufacturing of various metallurgical accessories, to provide enough customer satisfaction service, product quality is stable and reliable, welcome to come to consult and purchase. The light burned magnesia pellets manufacturing quality is superior, the price is reasonable, welcome to contact with us.

The series of metallurgical auxiliary materials can be widely used in national defense, medicine, chemical, paper, shipbuilding and other industries. It can be made in the building materials industry: tire board, particleboard, thermal insulation columns, railings, faux marble, asbestos tiles, common tiles, wallboard, floor laying. With the progress of science and technology, light burned magnesium powder is more widely used, can be used for civil products, heavy and heavy mechanical packing boxes, packaging bottom beam, high temperature refractory materials, but also can be used for making beautiful and generous furniture with high gloss, can be used for casting models in the mechanical industry.

Magnesium oxide (MgO) is commonly known as magnesia, light burning powder, magnesia powder. The density is 2.94, and the material belongs to white powder. It has a melting point of 2,852 ° c and a boiling point of 3,600 ° c. Soluble in acids and ammonium, insoluble in water and ethanol. The specific surface area is 180m2/g at the calcination temperature of 400℃. At 1300℃, the specific surface area was only 3m2/g. It is deliquescent in the air. It belongs to the gas rigid cementing material.

Generally speaking, the light burned magnesia pellets manufacturing is mainly made of magnesium oxide as the main raw material, while adding water and binder through mixing and high pressure ball.

It is mainly used as the slag protecting component regulator of converter slag splashing furnace. Because slag splashing requires slag to have proper viscosity and fire resistance, reasonable slag composition is the key to implement slag splashing. General slag can not be directly splash furnace protection, need to add a certain amount of magnesium oxide ball to adjust, at the same time replace the use of dolomite, reduce the amount of slag, increase the content of slag MgO. Since MgO is a high melting point mineral with a melting point of 2800℃, the increase of MgO content in slag increases the viscosity of slag and improves the refractories. Slag is more easily combined with furnace lining to form an effective protective layer of slag on the furnace lining so as to improve the life of furnace lining and reduce consumption.

We are professional refractory metallurgical material manufacturer, light burned magnesia pellets manufacturing reliable quality, reasonable price, export to many countries and regions in the world, you are welcome to come to consult procurement.